-

Posts

1,245 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Collections

Everything posted by Goce

-

Yes, niva's have tbi, and full injection, they are still sold new here. I can buy one like that but having to deal with them. The ecu's and other components are of poor quality. There ecu is made by bosch but is not even sealed, the circuit board is worse quality than on children's toys also i'm not planning to run it full time on petrol i like the programmable ecu because i can run 2 sets of injectors and two different fuels like on my 405 Mi16x4.

-

Last few years i've been wanting to do a programmable engine management. And with the new engine for the little niva i've been thinking what if i make it EFI. With my low monthly pay even megasquirt is too expensive, but i've found this ECU based on the MS3. I've never hear about it, has any one used them or any advice how to get cheap engine control unit here in europe. Many sellers won't even send them in Macedonia. https://sptronics.com/product/ems300-engine-management/

-

Today i had some time to spare so i decided to clean all the parts like pistons both sets then i took apart the conrods from the pistons. Took off the screen from the oil pump, check the inside it looked alright, clean every part then assembled the oil pump and stored it. I need to clean the conrods and pistons one more time but from what i've seen they can be reused and are in good shape. The engine block looks to been line honed at the main journals i need to check my micrometers and give everything a good measuring. Finally i wanted to compare a Vw 1.9 tdi conrod to the peugeot one. Peugeot con rods are way bigger thicker and fully forged. The bent one is from a Vw.

-

Joe's '91 405 Mi16 (and '90 SW and '92 Mi16)...

Goce replied to 91MR2's topic in Member build threads

Haha, i just did the same job on my brothers Skoda, but typically my luck the valve cover contains the camshafts. It's a much harder and more involved job, because i had to deal with the timing belt also i have to pump down all 16 hydraulic lifters. And the drivers side brake caliper was so stuck the steel piston broke on removal, discs, pads everything was cooked everything got changed. One by one you're doing great job. -

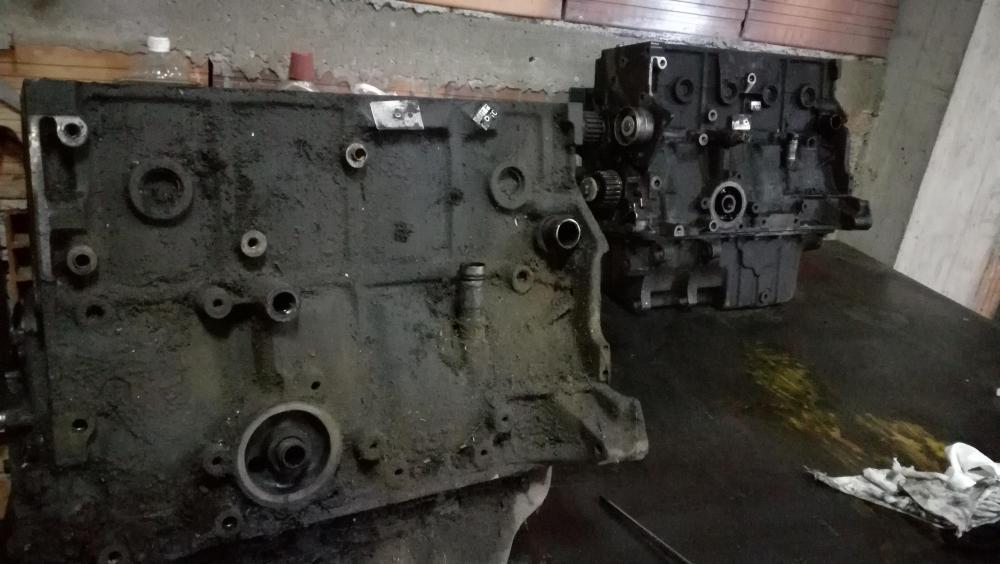

Today i find some time to spend in the big garage. I clean some parts of the turbo engine, also went thru my spares found me a spare set of rods and pistons for the turbo engine, also found me two oil pumps one form a turbo on the left and N/A on the right. It's obvious when you look at the housing for the pump gears. The con rods of the 96 engines have been know to snap, the other set i've been saving are from a 92 D8C engine code and are known to be the toughest factory conrods. The crankshaft is machined 0,5 mm under and is in excellent condition.I did manage to get the engine block clean in the wash tank, hone the cylinders just to clean them. Now both engine blocks are ready to get the cylinders measured and the deck resurfaced.

-

Today i found the time to disassemble the turbo short block. First the oil pan come off, then the oil pump. After that pistons come out one by one, then main caps and last to come out was the crankshaft. From first looks the crank has been machined its 0,5 mm under, the bearings are fm so they are good quality. I already know the pistons are oversized so this engine has been completely rebuilt, but when i check the oil pump its from 96 same year as the engine. Who ever rebuild the engine did all that machine work new parts and left the original oil pump. Also the engine block looks to been line bored at the crankshaft bearings, i'll be opening that pump and probably replacing it just for a piece of main.

-

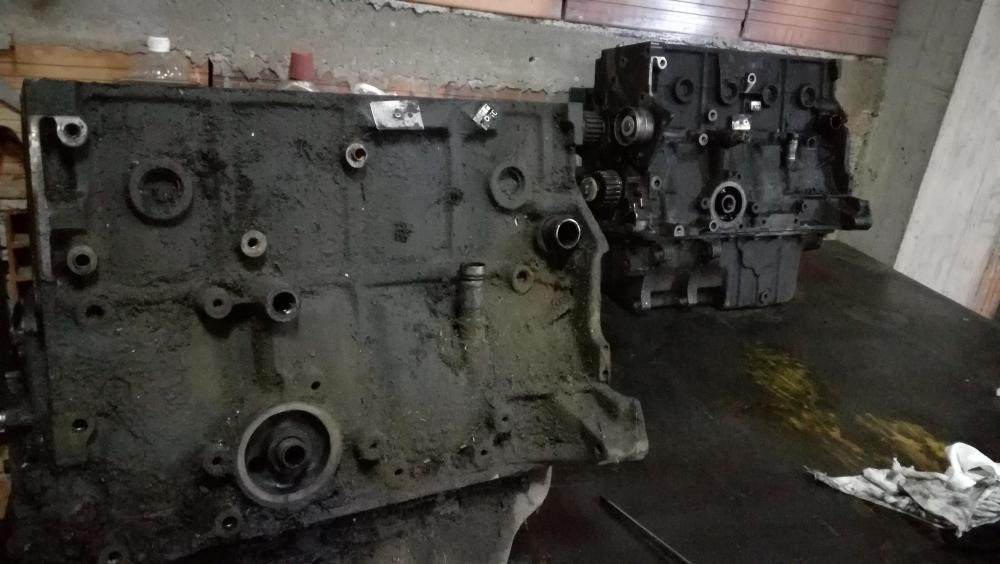

Today i had some time to spare so i got in the big garage to cleaning engine parts. One by one all the parts got cleaned and stored, i only stored the crankshaft i wanted to keep the crankshaft oiled. Then i moved the engine block in to my cleaning tank, first upside down, gave it a quick clean inside and a bit outside. But the outside is very dirty it will get a pressure washing after the machining. After the cleaning the cylinders got honed, my cylinder bore gauge is still in transit so i got me an piston ring and measured the low spot and is not too bad, i'll check when my tool arrives in the meanwhile i'll try to get it resurfaced. My work table is now empty for the next engine block to get disassembled.

-

Today i got back to working on this project. I have two lower ends to take apart, one on the left is N/A, the one on the right is Turbo. Everything is different even the block casting is different. Started on the N/A block, took the oil pan, there is some slage but not too much. Took off the oil pump, front cover chan drive then i moved to taking out the pistons. The cylinders have a good size rige at the top so i used my cordless drill and a hone to knock it down to get the pistons out without damage. I've order a cilinder mesuring bore gauge and i'll see if this block is in usable spacs or it needs to get slives. At this point i stopped i'll washed all the parts before taking apart the other block to i can arrange them not to get them mixed, the pistons, and other parts seem to be in good shape. The crank has couple of scratches but they don't catch my nail, also i do have 3 more cranks in excellent shape. Little by little they are coming alone.

-

The recently resurfaced engine block got clean out and reassembled. Today i started with taking the oil pump apart, it is in excellent shape, clean out everything put it together, its the original with 1/4 million km on it from 1994. Then i clean out the oil pan again no real sludge just old gasket to clean out, decided to use only silicone no gasket. Then i oiled the cylinders and heads surfaced and dropped few pieces of paper to protect it. Then i lowered the complete block from the table to wait till its head gets done. Next i lifted two engine blocks one turbo other N/A i'll be taking them completely apart, and getting them ready to go to get the cylinders hone and resurfaced. The difference in the block casting is very obvious which one is turbo.

-

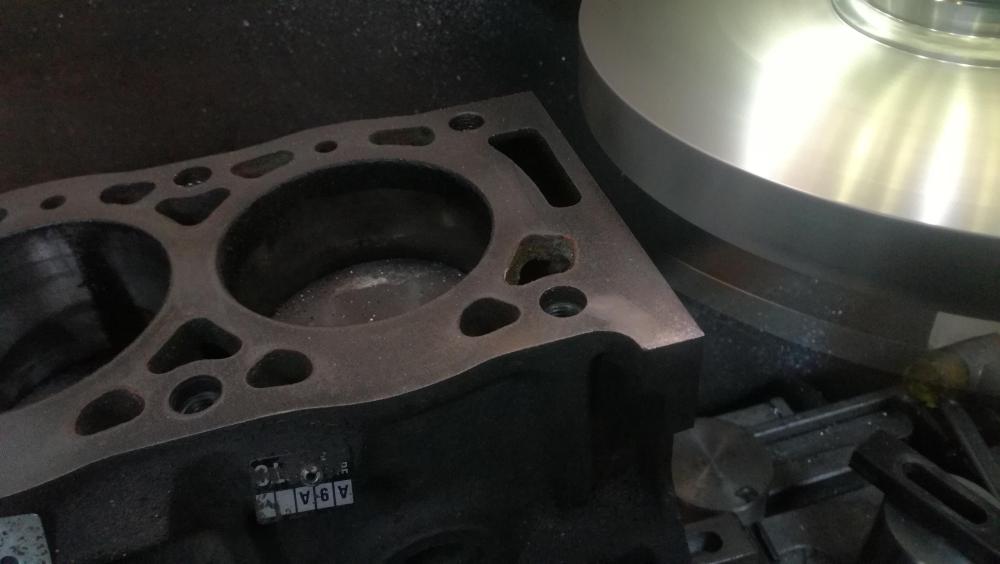

Last few days i've been asking around at machine shops to get the cylinder heads resurfaced. The peugeot cylinder heads have around 22 degrees at the camshaft flange in other words mounting them to a mill is difficult without a bunch of set up. A friend who is doing resuficing on a mill actually ask me how to make a fixture to hold the heads straight. After looking thru his and my scrap piles we found a peugeot cylinder head that was beyond repair. So i took it home, washed it, knock out all the valve guides, frizz plugs and any other steel to make it lighter thinking i have to cut it. Lay it in a table and drilled out the threaded holes so the studs from a good head can lock in them. Grab a good head from the shelf and it slotted in and is perfectly level. The plan is to get the jig head resurfaced first to keep the heads level. It may look weird but in my mind this a good solid piece of aluminium that is already at the perfect angle and height.

-

Last few days i've been calling around machine shops to get the cylinder heads and engine blocks resurfaced. No machine shop in my city is still working the corona virus closed them all, the closes is in the main city and they are booked till new year also there price seems really high. So after seeing my options i consider buying a big milling machine but decided i don't have the space to store it. So i call a friend who has one and we determent i need to take the oil pan, oil pump and clean the flange. I did that loaded it in my lada niva and took it to him, it's heavy so i regretted not taking the crank out. This is the XUD7 engine block and with 0,04mm clean up but we made one more pass to get better surface finish and took a total off 0,08mm, i was expecting to have a bent block because i was told it overheated badly. I'll have to clean out this engine block very well now to get all the milling dust off. The surface finish we achieve is almost mirror finish much better then the factory finish.

-

Europe 2023 - Plus 508 SW Hybrid review!

Goce replied to Mike T's topic in Trips, Adventures, & Events

What a trip, i really like that silver color, looks good in any light and shows the body curves very well. -

Well this project has slow down but not stall, i've been busy but i found time to make a shelf and store the heads and head parts. More to come.

-

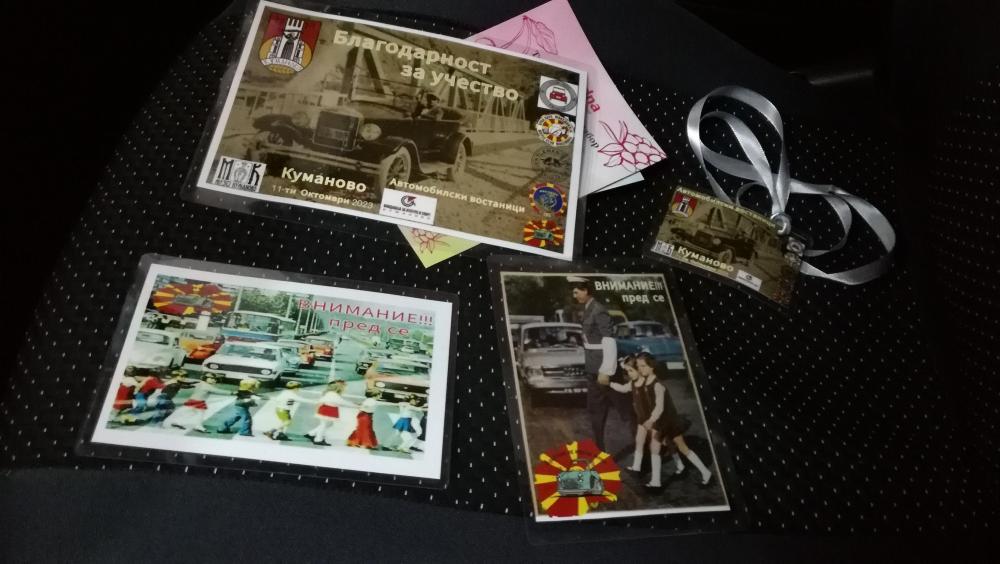

On the 11th there was the first classic car show in my city. For a first show if its type there was lots of cars and people, so i wanted to share my experience at it. Tehicly my 405 Mi16x4 is an oldtimer at 32 years but i have couple even older cars like my 69 fiat 600 wich is taken apart and my 82 lada niva wich is registered and in dicent shape. The car show was in two parts first at the city square, my niva had no issues driving over the curb, couple of the Mercedes scraped and a mk1 golf got stuck. The cars shown had from a 41 opel kapitan, dodge power wagon, to renault 18, citroen DS, alfa spider and others. The other part of the show was 28km away in ASNOM memorial centre in pelince, it was a sight to see around 60 chrome bumper cars going down the road. The willys jeeps were the slowest which i over take just the corvette left me in the dust, at pelince the atmosphere was much more relaxed. Barbeques, lawn chairs, fresh air and even some new cars show up, same year lada wagon parked next to mine in original paint. I hope you like seeing the pictures. P.S a Local news outlet made this montage, maybe you like videos more than picture

-

I have a ZPJ 3,0 on a pallet from my 605, i've wired it to run, about 10 years ago. Now is not accessible but when i get some spare time i'll try to dig it out and take couple pictures wich cables are for power.

-

Today i spent an entire evening pressure washing the remaining 3 cylinder heads, i also washed 3 of the roker covers. You can see in the pictures it got dark on me during the washing, I spent lot of time with the oven degreaser and a brush scrubbing. No real suprases only the know good turbo head has lots of corrosion from not running coolant.

-

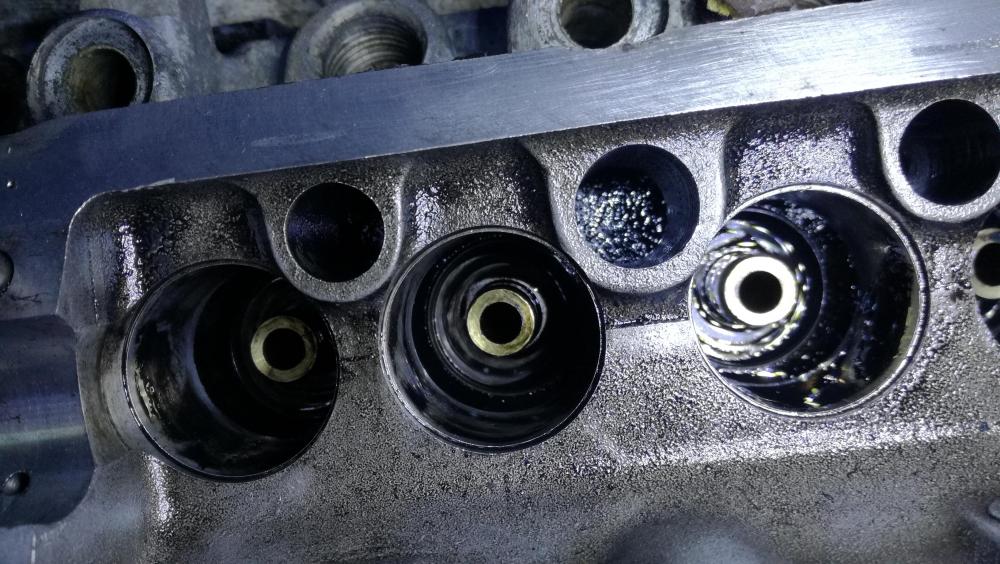

Today i got one more cylinder head clean up. I wanted to clean up more but i did not have time. This time around i clean up one of the cleaner ones, this head was clean on the outside but inside i that lots of oil gunk. This is the one without oil seals. Most of the carbon come out of the intake and exhaust ports but there's still some to come out, i'll use a wire brush after the resurfice. This time around i used compressed air and oil to protect the steel valve seats and bolts from rust.

-

With two full time jobs, i've been very busy but i managed to find time to pressure wash one cylinder head, i somehow picked the dirtiest one. This one is of a 92 XUD9 that come out of a peugeot 309 engine code DJZ. The condition is decent, it has some corrosion in the coolant passages also couple of broken bolts, but the camshaft journals are in good shape and no visible cracks. Cleaning the head with degreaser made a mess of my driveway also i looked like a dalmatian. I'll try to wash more parts at once next time.

-

The 205 that the engine come out of was 1994, but it was obvious that cylinder head was changed, it was cleaner. Also i've seen 21 date year cast on the head, perhaps someone use the valve train of an older head but that doesn't explain the valve guides. The casting code is same as all the others N/A heads i have P08, the turbo heads are P06 casting. Very strange, perhaps i should measure the cylinders to check if someone has put XUD9 pistons in it.

-

Today i took apart all 5 cylinder heads. All parts are organised i had couple of surprises. There is lots of corrosion in two of the heads, one has broken camshaft cap, almost all seem to had some work done on them. Many have evidence of replacement valves and cam caps, this engines when they brake the timing belt from not changing the belt on its intervals they bent valve or two but also brake the camshaft and the camshaft caps. The most surprising was the XUD7 head i took of the french engine it has green dual spring on the valves and there is not valve seals, the valve guide is not even machined to aspect valve seat. In so many XUD engines i've work on i've never seen that, i'm not sure why are there dual valve spring or why it doesn't have valve seals, there is no evidence of it burning oil also.

-

Last few weeks have been very busy for me, the start of a new school year and all but today i found me couple hours to spend in the big garage. With the big table clean, got me few egg cartons and started to lay down the cylinder heads on them. I found 5 heads some of them partly disassemble, the plan is to disassemble them, wash them and test them for cracks if fine continue and refurbish them. First i need to take them apart, they are incredibly dirty, just moving them got me incredibly dirty, and that small of used diesel oil. I usually keep the valve train in order as they come out to use them in the same order but that takes time and i'll try to work on them tomorrow.

-

Today i had little time to spare so i decided to start on getting things done on those engines. The xud7 cylinder head looked cleaner so i decided to take it apart first. First i took off the cam cover, and first ting i noticed the cam caps are wrong way around, and some one has marked the head like they are installed, the baskets look good but first one i took off i found this, someone did not have thin enough adjustment shims to adjust the valves so he grounded the shim. Seeing that i stopped, i was dealing with a someone else's hack work and that is never fun.

-

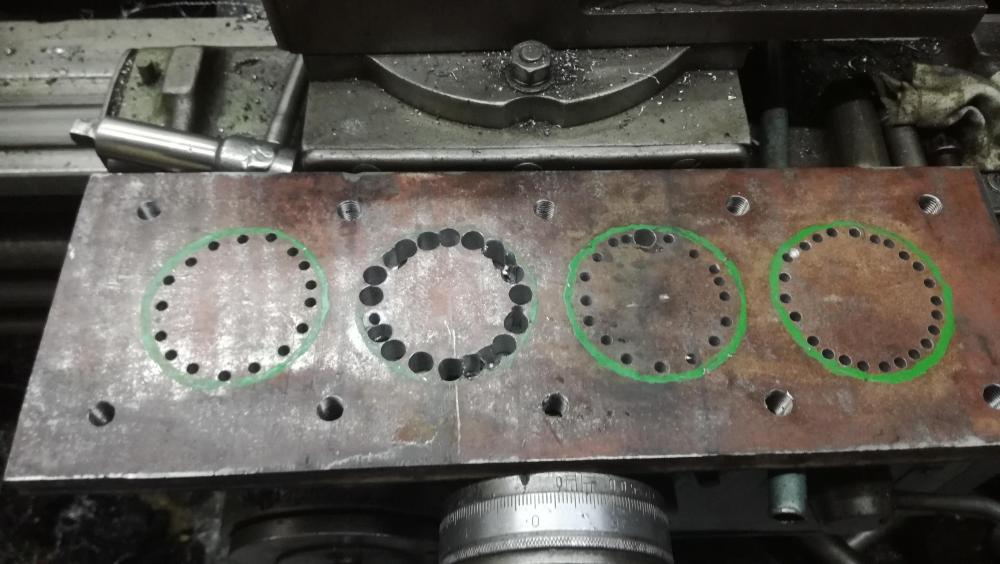

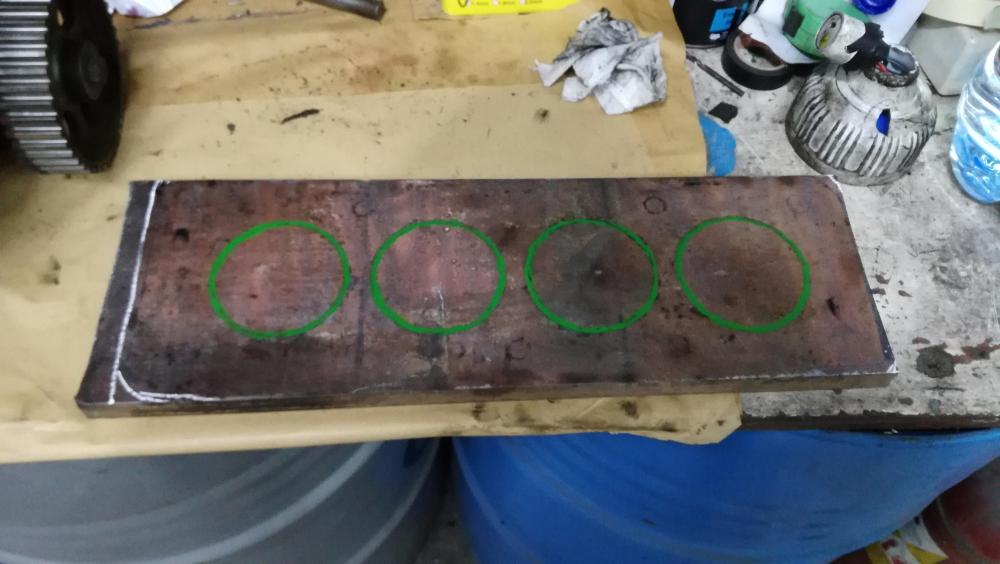

Some time ago i started making this part but every day job and other project pushed it back. Also my drill is very underpowered and overheats easy, so even when i had time it will over head and i'll move to another job. But little by little i drill all the holes and removed the big holes, drill and thread the bolt holes. At the end i use a hammer to smash them out, now i'll find time to take it to my friend's shop and get it machined on a mill. I need to make some more storage space, my XUD storage palce is overloaded.

-

Why did you get 4x114 wheel adapters, that size is also rare, logicly i would expected 4x100 or 4x108 to keep it in peugeot family, any reason?

-

I've been asking around for a good machine shop to test couple of cylinder heads for me, but all the advice i got was they all just guess. Two of the fore mechanics who rebuild engines every day said they've had many instances where the shop garantie the head is good they refurbished it install it and creates more pressure than before. They explained that the machine shop never heat up the heads and test them with only a bar or two air pressure because there machines are so worn out they blow out. Also this particular cylinder heads are very difficult to be sure because they need cut out in the pressure plate for the pre chambers. With that in mind i decided to make me a specific plate so i can test them myself. Started with a 20mm plate a bit over sized, which i cut one side to shorten. I marked all the holes i plan to make except for the pre chambers those i'll make on a mill alongside cutting the cylinder bores and facing it on both sides that will take off lots of material and will end up with a thinner plate. I started to drill out the bulk of the bigger holes on my small drill but its overheating constantly. This will take a long time.