-

Posts

1,299 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Collections

Everything posted by Mike T

-

Engine's out again, to replace the rod bolts and put the replaned head on again in comfort on the engine stand. That's my son in the photos wearing the Peugeot overalls.

-

-

Got one of the two door seals done! Original part from 1975 (replaced then) and will be installed to replace the ill-fitting modern replacements shortly. Now I have to do the other side - clean the rust residue from the rubber then insert the plated clip strips.

-

-

Ah man, even the MI16 has the cheap two channel injector circuits? It thought that was an XU9J2 issue only. "storing" the charge next to a closed intake valve sounds a tad hokey to me.

-

I had a good look this morning. It's an honest old car: floors seem good, spring towers are good, front and rear fenders need work. About ten grand in paid bodywork and half decent Ivoire 1010 paint would set the issues right I think. Engine runs, and is the original three main bearing XC version. 1961 models are unique - cutout rear bumper for central-ish exhaust (this one has a later pipe fitted), specific rear reflectors, wide side stainless steel strips on the body, large vents on the dash, old style steering wheel, specific door trims and headliner, and more....

-

https://www.internationalmotorsports.com/inventory/1961-peugot-404-langley-bc-v1m-4c2-11123985i She's looking good, I will check her out Friday to see what the story is but initial indications are positive. Asking price is a bit high but condition could bear it out.

-

Today I got a rebuilt Hydrovac booster from Todd Langton, Le Club 404's USA representative. I'm the Canadian representative of the club but Todd has more stuff! He bought this apparently unused NOS unit, which nevertheless had surface rust, several years ago, and had it rebuilt by White Post Restorations in Virginia in 2018. The unit in my car was NOS in 1993 when I bought it, probably made around 1970, never rebuilt, but mounted on the car with brake fluid and all for 20 years. I was pretty silly to think it would work after all these years. When the engine is out in October I will remove the unit I bought in 1993 and install this one, and (I hope) successfully bleed the system before reinstalling the engine.

-

These are the wrong bolts; I got the correct ones today (below) from Joern Haarmann. The precision-machined shank is a lot longer on the correct ones than on the ones above. This machining accurately locates the lower portion of the big end. Some are advising me to not bother because none of these re-used rod bolts are known to have broken, but I will be changing them, so the engine is as close to new as possible.

-

Nice!

-

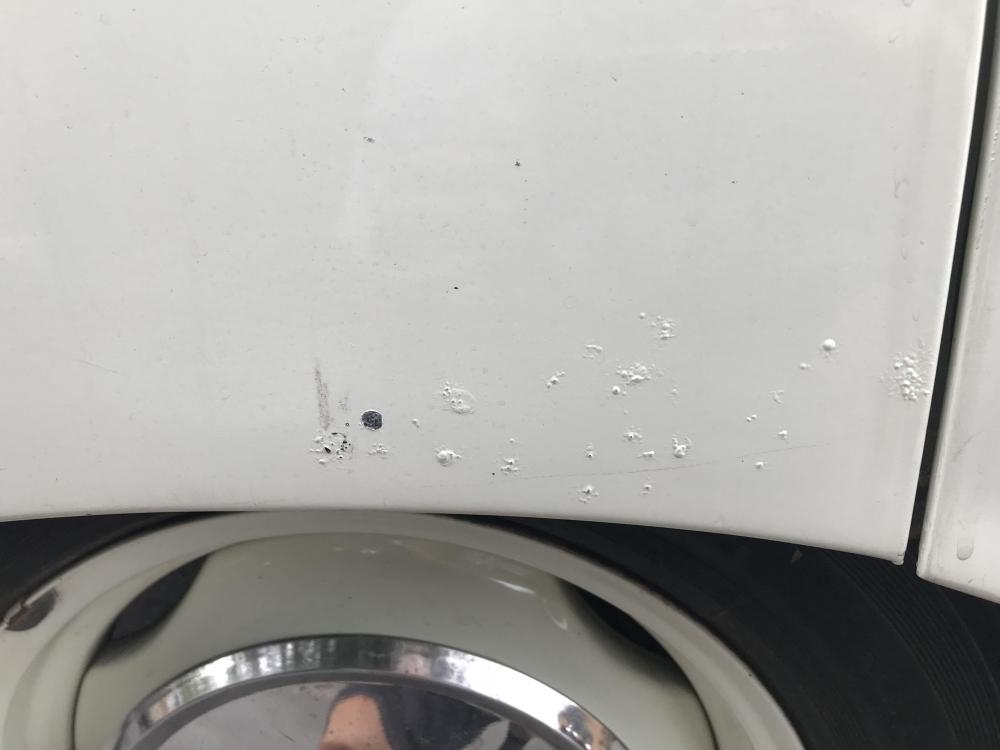

So the rusty bits you see in the photos above are at the plating shop in Victoria now and I should get them in a couple of weeks. Meanwhile I ordered some new Flitz polishing paste to rejuvenate the other door seal's rubber and remove the rust stains and white paint overspray. I ordered 8 rod bolts (NOS) from Joern Haarmann and those should arrive in a couple of weeks. The garage is full of old kids clothes right now and those need to be washed and donated before I'll have room enough to do anything much on the car! I also need to buy a piston ring compressor sleeve to remount the pistons once the rod bolts are changed....

-

I took the advantage of the current pause in work to clean the old door seals. The new replicas available these days are too thick and press too hard against the doors when shut and because the rubber of the originals seems to be in decent condition, I thought I'd spend a few hours cleaning one up to see if my plan to reuse them would pay off.... Before: Before (inside the seal where the metal clips are placed): After: After (inside the seal where the metal clips are placed): Thanks to Jérôme Roussel in France for giving me 1.5 metres of metal clip strips, to replace the 1.5 metres of my originals that rusted to FeO2 powder in the 5 years these seals from 1975 were on the car, and the car on the road. These will all be de-rusted and electroplated in Cadmium and painted, then reinserted into the seals. As I noted, the seals were bought by the previous owner in 1975 at Jay's British and European Motors - I still have the invoice - and they were on this daily driven car for five years. After that the car was in a garage and so the rubber is truly in excellent condition. Three hours or maybe a bit more with Flitz polish turned them from a rusted, dirty mess into what appears to be nearly new and very soft and supple rubber! After a good wash with a nail brush, the cleaned seal was treated with this Würth stuff and wow did it make a huge difference! The door-mounted striker plates are not as good looking as they should be so they too will be replated when the seal clips are done. It seems that the spare connecting rod bolts I have are a bit too short so I'll be ordering a couple of sets from Europe shortly.

-

NOS switch on the console? Nice job

-

Well, the pause has been very good! I've had a chance to look more closely than I did before at the preparation of the internal engine parts. Basically, I need to pull the block out of the car again, put it on the stand, and whip put the pistons and rods....because I did not change the connecting rod bolts. I had read in a Peugeot service Bulletin many years ago that they were no longer recommending systematic replacement of rod bolts at engine reassembly because the rod bolts were knurled and mounting them in the rod would ever so slightly affect the position of the rod cap and therefore the bearing positioning, which is BAD. That is correct, but the bulletin was from 1973....and my car is from 1966. In 1966 (and probably up to 1970+) the 404 rods did NOT have knurling in them, but rather tight smooth sleeves to fit them in the rod holes. So that Bulletin does not apply to an earlier 404. Further, the workshop manual for the 404 KF2 states that the bolts and washers have to be changed systematically after every dismantling. In other words, they are stretch bolts. The good news is that I have a set of eight of them, new old stock, with new washers and nuts. The bad news is it means a fair bit of new work. But: better now than later! In 1987 when I did a basic rebuild on another KF2 engine, I did not change the rod bolts IIRC but that was as I say a rather basic rebuild and even though it was driven hard for 100,000 more km and never seemed to have a problem, I'd rather do this engine 100% properly. The eight top bolts in the photo are from a 404, NOS, and the bottom one is one of six (!) knurled ones I have from a later Peugeot engine, possibly a 504.

-

Hoping for the best!

-

Got the head back today, it's very smooth, in fact I had to move out of the direct reflection so you can see it properly.

-

https://www.amazon.ca/gp/product/B076ZYJPGR/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

-

I heard back from the shop today. When they were fine tuning the surface a couple of days ago, a couple of low areas were apparent around where the head was weeping. In the end about 0.38 mm had to be skimmed off to level it all up. So, that is encouraging news.

-

Well I ordered one that's made in the USA and should be good - but it was only $60 so it's worth keeping!

-

A generous offer! Will follow up when I get one....

-

..or I could buy a decent mechanic's straightedge to check the block I guess. Might be money well spent.

-

Yeah, will hope for the best. I do have a spare block, but no "matching numbers" if that's needed. Liner protrusion is fine.

-

I took both cylinder heads to the workshop this afternoon and - surprise - the new head is perfectly flat. The rocking was caused by the original head. The old head is slightly crooked though Evan said it's not what he'd call "warped" but could use a skim. He offered to fine-tune the surface on the new head at no charge to give the best possible chance for a good seal with the Reinz. I think I'll put the head back on after she's back.... And eventually have the original redone with new guides and seats and store it as a spare.

-

Blast from the past: John Coltman's 404 Injection

Mike T replied to Mike T's topic in General Peugeot discussion

Here's John's 504, equipped with a 3 litre V6 - which burnt in 2018 and is therefore no longer around. Me and John around 2016 - with another of his 504s. -

The machine shop has contacted me just now and asked me to bring the head(s) down to them for checking, the shop indicated that their records showed that it was not checked for trueness because it was NOS. So we should have a reasonable solution sometime soon. In the event the NOS head is too warped to rectify (up to 1 mm can come off before compression ratio starts getting too high) then the old head will have to be redone with new guides and seats. I'll bring both down there soon.

PHB489(BC)-01c.InternationalMotorsports.thumb.jpeg.abcc1abc0e658e7fd7aebec07813fdb2.jpeg)

PHB489(BC)-04.thumb.jpeg.164a499f7e771844438ab1ff17e152c6.jpeg)

PHN489(BC)-03.thumb.jpeg.5ba7b77e6c8c59b87cb4e1f0f59637b7.jpeg)