-

Posts

1,299 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Collections

Everything posted by Mike T

-

-

-

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Popped back over to the UK for a two week visit until April 5th. This time we rented this 2008-based Vauxhall Crossland. Not very impressive to drive, barely more economical than the Volvo XC90 we drove there last year, despite its puny 1.2 3 cylinder engine, and the suspension was nasty.....which coincides with what a friend who rented a 2008 in Britain last year concluded. Here in the Cheviot hills, crossing into England from Scotland, on a B-road. -

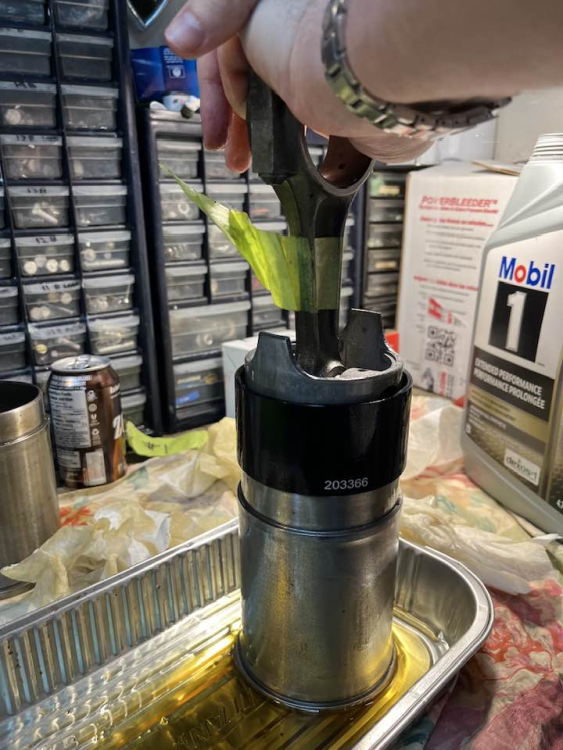

Did jack squat on the car until just after Xmas, when I repainted the three Purflux fuel filter/decanter bodies I have in POR-15 - the one with the decal is for the car. In a few weeks' time I should be able to put the brakes back together and then get the engine assembled.

-

Aftermarket Engine management Programmable ECU

Mike T replied to Goce's topic in Technical Discussion

Interesting. The Nivas here had General Motors monopoint injection and it was bulletproof. -

Aftermarket Engine management Programmable ECU

Mike T replied to Goce's topic in Technical Discussion

Nivas sold in Canada with the 1.7 engine had GM monopoint injection and they were super reliable compared to the Russian carb on the 1.6. -

Any Peugeot owners from Vancouver, BC?

Mike T replied to 85PugSTI's topic in General Peugeot discussion

Correction, nearly 3900 cars...... -

Any Peugeot owners from Vancouver, BC?

Mike T replied to 85PugSTI's topic in General Peugeot discussion

Welcome, Tom! If you have a Peugeot, I'd sure like to know which model, the serial number and see a photo. I have a Canada-wide Register of Peugeots and so far nearly 3800 cars are on the list. The best French car mechanic in the Lower Mainland was John Gaughan in Abbotsford, but he retired a few years ago. An absolute wizard. These days it's a DIY prospect more or less for French car owners. Even Marc is rarely at his place, just his employees....Lionel Hondier does Citroëns in Langley but he may not take on Peugeot work. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Erratum: the battery in the 508 is 11.8 kWh, not 17.8 kWh. Still, the Autobahn recharge is more expensive than gasoline.... -

That's Victor van Tress' car with him in it. SCCA champion and also star of the "bedroom" commercial. The same car.

-

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Actually the massive Volvo XC90 B5 mild hybrid was a vehicle that impressed us in many ways. And it only drank 1.6 L/100 km more than the 508. The Volvo's not my preferred style though. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

The new 3008/5008 is hideous and I'd never want one! -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

2024 Peugeot 508 SW Hybrid 225 review - Mike Tippett Peugeot has a long history of making very good and high-capacity station wagons, especially in the post-WWII period: the 203, 403, 404, 504, and 505. They also made smaller ones that were not really first and foremost designed as heavy load carriers and among those I’d note the 204, 304, 305, and the 405. Before seeing the 508 station wagon in person, one could have the expectation that it’s more like the load carriers of old rather than the “lifestyle wagons” typified by the 405 if only because it’s about as long as a 504 station wagon; but that would be wrong. The 508 SW is not particularly capacious and its road manners are more like those of a sports sedan than a utility vehicle: • it’s rather low to the ground • rear legroom is OK but not especially generous • there would never be room for a third row of seats • the height of the load area is not all that great • the suspension is quite firm, and although it’s not uncomfortable on the road, it’s no 504 In my case, the 308 SW Hybrid that was reserved from EuropAuto.ca (upgraded at no charge by Peugeot to the 508 SW Hybrid) was chosen as the vehicle we would use in Europe to take 4 people and their luggage on a 2000 km trip through France, Belgium and Germany, and thereafter to take my wife and I on a further 5000 km journey through the entire Iberian Peninsula. You would imagine that a 308 SW or 508 SW would have no trouble swallowing 4 large suitcases and some smaller bags. I can’t speak to the 308 SW but I expect that it’d have been tighter than the 508; to get the luggage into the 508, the load area was packed to the ceiling – I do mean tight to the ceiling, to the point that the headliner was heavily compressed – and on the rear seat were two bags as well, with passengers on either side of them – blocking the rear seat area air conditioning vents. A 504 station wagon would have had no problem with this amount of luggage. OK… it’s not an old school capacious Peugeot load carrier…. The 508 Hybrid has a 180 HP 1600 cc turbocharged engine – the ex-BMW-Peugeot joint effort that started with a terrible reputation but seems to be better sorted now, with a total powertrain output of 225 HP counting the electric motor’s contribution to the effort. The power units are connected to an eight speed Aisin automatic gearbox. The electric motor has two sources of power: a regular hybrid buffer battery that can recapture kinetic energy and also the plug-in battery, that enables the car to operate as a full EV for a limited distance. More on this later. This technology is heavy; the car weighs in at about 1750 kg with the electric glass sunroof, and if you can’t plug the car in, part of that mass is dead weight. According to the French government certification sheet that came with the car, the top speed is rated as 250 km/h, but most other sources suggest 240 km/h is the limit. Either way, it’s reasonably fast. Acceleration is good at 0-100 km/h in under 8 seconds. We took delivery of GR-417-KF at the TT delivery centre at CDG Airport on October 15, 2023. It had 2 km on the odometer and the 43 L fuel tank was full. The car is light grey metallic with 17-inch wheels with W rated (270 km/h) tires, while most of the rest of the car matched GT specification – heated leather seats, lane keeping assist, electric sunroof and more, in Britain the “small” wheels would supposedly make it the base “Allure” model. Could British and French wheel specifications be different? The car has a 2.3 kW domestic power plug charger and cable that fits into the e-plug on the left rear fender. During the 23 days and nearly 6900 km with the car, we only managed to use this charger at 4 hotels, for a total of 7 days, or around 30% of the time. The first impression is that this is a low car, and the pronounced bolsters in the cushions of the front seats made ingress and egress more difficult than it should be. The seats had two electric adjustments: lumbar support and cushion angle; the other adjustments were manual. Both front seats were heated. Peugeot’s thermocouples in their cars’ seats seem to be very sensitive, as the seats never seem to get particularly warm, except on the first bit of a drive. The windshield also seems to be shallow in the vein of a 1960s car, and the low roofline limited headroom in the rear especially, though likely not as much as in the fastback – sedan – model. Peugeots have always had excellent steering and despite the electric assistance, the 508 is no exception. Straight line stability is exemplary and the weighting is perfect. I engaged the lane keeping assist during our time with the car and I think it is overly sensitive and frankly easily confused at motorway exits and where lanes merge. Perhaps its main benefit is detecting and correcting tired drivers. The car would occasionally remind us that we had been driving for two hours and it was time to stop. The 8 speed automatic transmission was very good and despite having paddle shifters fixed to the steering column, I very rarely used them – mainly when descending really steep hills and not using regenerative braking. The integration of the hybrid drive with the gasoline 1598 cc unit was OK but occasionally there were clunks and lumpiness as the mode changed from full electric to hybrid. Very usefully, the cruise control would maintain the set speed even on steep downhill sections by using kinetic energy recovery for recharging the batteries. Even if the car could not be plugged in, there was always hybrid function available so long as the regenerative – as opposed to plug-in – battery had any power from braking and other sources. A good example of this is the day that we drove from Mojácar to Granada – a 200 km run. We left with a full plug-in battery, showing a potential range of 68 km due to some local EV driving the day before. Getting onto the Autovia about 10 km after leaving the seafront Parador, the electric range was still showing around 46 km but once on the highway, at the 120 km/h speed limit, the electric drive diminished rapidly, lasting only about 38 km in total from the start. At that point the gasoline engine lit up and the regular hybrid system was active. When we got to Granada, I decided to drive up Sierra Nevada, a climb of about 1900 metres from Granada’s 700. The plug-in battery had been a 0% for most of the day and of course climbing the mountain was not going to improve that. But the descent, done using cruise control for the reason mentioned above, managed to recharge the plug-in battery to 47%. At one point near the bottom of the mountain, the kinetic recovery system was unable to maintain energy capture and I had to use the service brakes… presumably the circuitry was overheating and a pause in recharging was required. Otherwise, the battery could have made over 50% of a charge during this descent, which took maybe 20 to 25 minutes instead of the 3 hours it would take with the 220V charger. After about ten minutes, the kinetic recovery resumed normal operation. The same effect could be achieved using the brake pedal which also activates the kinetic recovery system, but I wanted to use cruise control so the service brakes were not used at all. An interesting experiment. Sierra Nevada is stunning by the way. Acceleration even with a full load of 4 people and too much luggage always seemed strong and torquey and there was never a sense that the car was in any way underpowered. It’s no drag racer but it’s very brisk. It was interesting watching the car’s on-board computer to see what the readout said when driving, particularly when the plug-in battery had charge. We once saw 68 km travelled with a fuel consumption of 0.0 L/100 km. On the drive to Granada, the consumption was 0.0 up to about 38 km and thereafter it climbed to just under 7 L/100 km at the summit of Sierra Nevada and then went back down to 6.4 when we arrived at our hotel in the Moorish Albaicin district, thanks to the 47% charge, which permitted 100% electric urban driving. We drove from Strasbourg to Munich but the Autobahn A5 is more or less a parking lot these days, with traffic having occasional bursts up to 160 km/h but lots of slow going. The A8 from Karlsruhe to Munich is not a lot better, with a massive rebuilding project that covered about 20 km. Once past Stuttgart, it opened up a little and my son-in-law was able to get up to 193 when a short window opened up in traffic. After the couple of days in Munich, Sandy and I were alone in the car heading to deepest Spain and the Autobahn 96 to Lindau was more lightly travelled and I was able to get above 230 km/h for a few seconds, but had to back off immediately due to the high closing speed on traffic up ahead, moving at a glacial 150 km/h or so. There is no doubt that the car will achieve its 240 km/h top speed rather easily, and so the 508 must be quite aerodynamic. The 508 rides well on the highway, reasonably firm and well damped. There was the odd occasion when it seemed as though more suspension travel would have been useful, though it never bottomed out on its bump stops. In town, the ride was a bit jiggly but larger bumps were handled well. The proximity sensors built into the bumpers were overly sensitive, beeping like crazy and showing red on the screen when there was still a fair bit of space. Which leads me to the GPS – it’s a TomTom system, and compared to the Google system in Volvo’s XC90, it was not very good. The main problem is that in cities with super narrow streets, it will direct you down ones that clearly are far too narrow. This happened to us in Granada, when we were headed to our hotel. I missed a turn and it recalculated, sending us down a series of roads that eventually got as narrow as the space between the car’s side mirrors. When I realized that we could not go any further, after a brief moment of panic (!) I managed to do a 100 point turn to get it pointing the wrong way down the one way street and to get out. This should not be a problem. Another thing that the Google nav does better is tell you where there is road construction, traffic congestion (and suggesting alternate routes). The 508’s system was good enough in normal circumstances but not in all. The 508 has interesting slimline LED headlights with multiple reflectors and a driver-selectable Auto function that operates the high/main beam in phases, depending upon what light sources are ahead of us. As a driver I appreciate its ability to illuminate parts of the road ahead while ostensibly not blinding oncoming drivers. Couple of comments though, as a potential long-term owner: I wonder what a component failure (e.g. light source) will cost to replace. My guess is the units are sold integrally at many hundreds of Euros. on the Autoroutes we were on with 4 up and luggage, the lights would not react to oncoming trucks in the other carriageway in time for the drivers, who often winked their roof lights and main beams at us. This could be down to the high driving position on those units along with median barrier blocking the truck headlights from the 508’s sensors. The headlights were also too sensitive to other light sources such as streetlights, where it’d still have been nice to have a bit more light. Of course, manual high beam is just a flick of the wrist away. Overall, I liked these lights very much. During the 6883 km that we drove this car, the average fuel consumption calculated by actual fills was 6.68 L/100 km. This compares to the 8.37 L/100 km that we managed in the Volvo XC90 B5 mild hybrid in the UK and Ireland over 4100 km, which was driven at 70 MPH on the motorways, a bit slower than the 508. It was a 7 seater, a behemoth of a vehicle, and yet reasonably economical. It makes me wonder what a plug-in hybrid XC90 might have done. We didn’t pay for any of the electric “fills” which were all done in hotel and Spanish Parador parking garages, which is just as well, because one place – an Autobahn rest area – where we saw a suitable commercial charger for the 508, it cost 68 Euro cents for 1 kWh. The battery holds 17.8 kWh and so a fill would cost 12 EUR. That fill would likely last 45 km in average driving conditions. On gasoline and normal hybrid alone, assuming ~7 L/100 km, that same 45 km would be about 3.5 L of fuel, which would cost half what the electricity did. Not a compelling case for EVs as touring cars. The 508 was returned to Peugeot at the CDG TT site on Tuesday November 7th and as is normal for this program, the car’s condition was not important and it ceased to be my property at 11:30 AM on that day. As it turns out, we had been rear-ended by a Fiat 500 in Le Mans the day before, but the damage was nearly imperceptible: a small scuff on the paint near the towing hook hole area, and a small chip in the car’s black diffuser. I told the Fiat driver to not worry about it and no exchange of information or constat amiable was filled out, which probably made his day. The question after all of this is whether the 508 SW Hybrid is a car I’d like to own. Maybe, is the most generous answer I can give. My wife did not like the seats and I too found them uncomfortable. We both enjoyed the Volvo XC90 – a vehicle type I generally don’t like at all – much more, with respect to comfort. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Car returned and I'm no longer the owner. Back in Canada after 6 weeks of hotel living - relaxing, believe it or not! I'll write up a detailed review of the 508 SW soon and post it here. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Seems as though I'll be a tad short of 6900 km when it goes back on Tuesday morning. Was rear ended today in Le Mans by a guy in a Fiat 500 - minor scuff on bumper - I let it go. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Lifetime FE earlier today: 6.3 L/100 km according to the OBC. It's likely to be more like 6.5 L/100 km when the car is returned at 7000 km tomorrow. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Made it to Chinchón. And - bonus - I got a charge point in their underground garage! Plaza Mayor: Stunning. We ate dinner on one of the galleries in summer 1988. 35 years later, we're back! -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Our Parador in Mérida also has a 220V plug for EVs so the 508 gets a battery refill - the first since Mojacar (also a Parador). Off to see the Roman monuments today..... -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Double post -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Comments copied from my FB post: Shift paddles - fixed to column and not wheel, not worth using IMO although helpful if engine braking is required and the recharge recovery is maxxed out or overwhelmed as happened on our 1900 m descent of Sierra Nevada.Seats look good, have electric cushion tilt and lumbar adjustments and manual fore-aft and backrest angle. Still not as comfortable as they should be. Maybe this is some sort of optional sport seat.Interior finish is very good, light years ahead of the last cars sold in North America. Limited rear legroom so the car barely passes the "me behind me" test...still, not bad. Luggage capacity is good but not 404/504/505 good. Power tilt/slide sunroof and power sunshade for it too. Auto dimming mirror. Sunvisors swivel but do not slide/extend back so of limited use for tall drivers. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

The car at the southernmost point of Britain - Europa Point Gibraltar - today. Off to Morocco tomorrow via Tarifa. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

Incidentally, the GPS directed us to this 2 metre wide road after we missed a turn. The tourists coming down it were shaking their heads, NO WAY! Scuff is nearly gone after a minor bit of polish with toothpaste. TT cars are not assessed like rental cars upon return anyway....no charge. Tomorrow we leave for Gibraltar and then Morocco for a couple of days, without the car, which will be parked in Tarifa. Photo from Sierra Nevada, about 2 km above Granada. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

GPS sent us on a strange route through the old Arab quarter which the car clearly could not fit down. Mildly scuffed a wheel attempting to get out of this jam. This is a very interesting city. -

Europe 2023 - Plus 508 SW Hybrid review!

Mike T replied to Mike T's topic in Trips, Adventures, & Events

double post