-

Posts

1,301 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Collections

Everything posted by Mike T

-

I got my second set of 0.5 mm oversized main bearings from Israel today. The first set (with the half red/half blue label) from Peugeot Classic in France had chattering marks on two or three of the shells from improper storage in the distant past. The Israel-sourced ones are excellent!

-

Good point. The first Purflux fuel filter assembly I had vapour blasted was the wrong one (from a wreck that had a lot of undrained water inside it) and it had very deep pitting cavities inside the bowl as a result. So the blasting shop offered to do another better one. This happened today and the result is much better mainly because the inside of the canister was far less affected by corrosion. You can see both here, with the better canister on the far right.

-

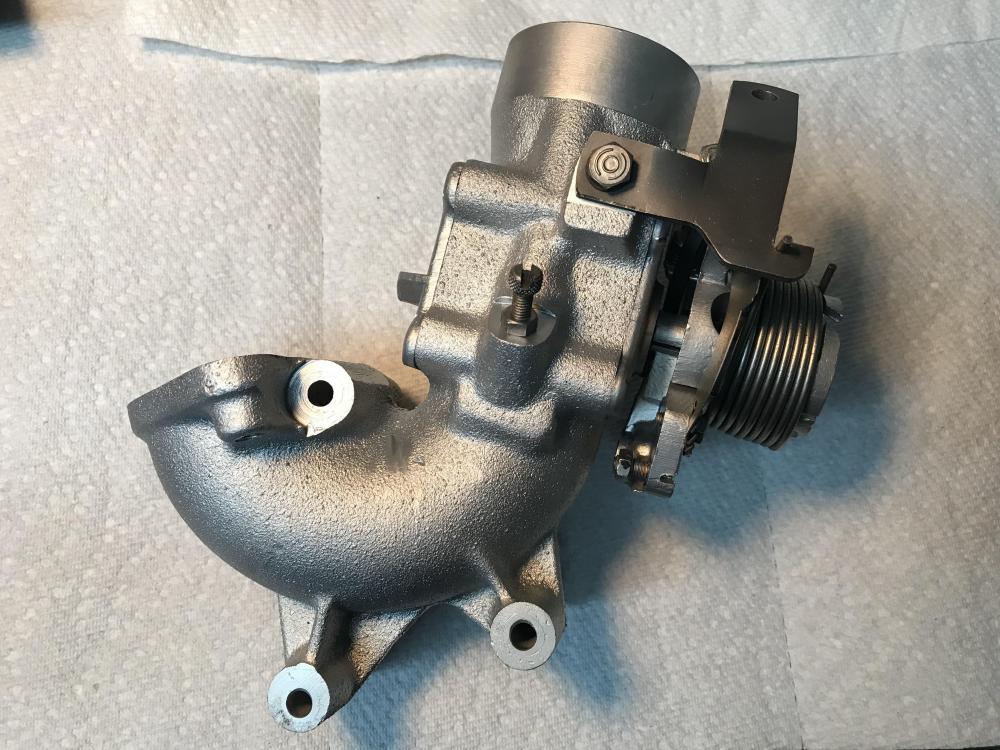

Throttle body is reassembled. The screws were staked at the factory because the distance between the two plates determines the clearance between the throttle body and the throttle plate. The large round inserts assure the air seal. I didn't stake the screws but I did put blue Loctite on them. The plates are snug to the throttle body but the screws are not "tight" but just touching the chamfered recesses in the two plates. Now that it is all together, the throttle action is magnificently smooth! I also took the wrong fuel filter for blasting so the vapour blaster guy will do the "correct" one for free on Wednesday! The inside of the filter bowl that he blasted has severe rust pitting and the "correct" one does not.

-

I picked up the vapour blasted parts this afternoon and took a few more photos. Very clean; the throttle body was disassembled by me for internal cleaning as well as the installation of new bearings. Driving the old ones out was easy - remove two circlips on the shaft end, remove the throttle spring holder from the shaft after marking its position, unscrew the 4 staked screws on either side that hold the bearings, tap the shaft out with brass drift, tap the bearings out with a perfectly sized brass drift (there is the smallest of shoulders available to do that). After its cleaned up I will reassemble it with the new bearings that you see in one of the photos. The old ones were shot, damaged by road salt I presume.

-

I'll get them ASAP and get better photos!

-

Got some teaser photos from the vapour blasting shop. I'll take more photos when I get the parts back. Looks good to me!

-

-

I was wrong about the main bearings 2 and 4...it seems as though they were an afterthought following the 3 main bearing engine but they do indeed have pressured oiling from the block, just not internal canals inside the crankshaft. Serves me right for spending too much time staring at the crankshaft yesterday! Is the 504 the same? 505 XN6?

-

The Peugeot 404 crankshaft sludge trap plugs are brass and have a large hex keyway. The threading into which they're screwed is staked, which damages the threads in one spot and so reversing that damage is required before they'll come out. I used a Dremel power tool with a dentist drill sized head to take the ridges off the threads by the staking. The hex tool will work sometimes, allowing you to turn the thing all the way out, though it likely will be stiff as hell. In my case, this tool worked one in four times. The other three were immediately rounded. So I took a different approach for those. I used a larger Dremel drill head to carve a small channel at each of the 6 corners of the hex depressions and then hammered a Torx-60 socket into place. Rammed it home! Using this approach on the three jammed ones made removal easy. I got a similar amount of sludge/paste out of all 4. I find it interesting that the 2nd and 4th main bearings appear not to be pressure lubricated at all

-

I don't know if having removable brass sludge traps in a forged steel crankshaft is a common thing, but Peugeots had that for a long time, from the 1940s through the 1980s. It's tempting not to remove the hex-headed brass plugs because they are staked in place and unstaking (reversing the damage to the thread is difficult and it's easy to damage the brass, in which case the plug will have to be drilled out. I am using a Dremel to do the unstaking. The first one I tried before the Dremel is now stuck. This one worked better. You can see inside the trap, there is a medium grey deposit that looks as though it might be part of the casting is sludge, the consistency of slightly moist clay. There is not a lot of oil passage left clear and a couple of the oiling points on the front centre and rear mains were partially blocked too. Ao, if restoring a Peugeot engine if the XC or XM/XN series, don't skip this step! I also got from Jean-Marc Faivre in France a free pair of the banjo fittings that my car has likely been missing for three years! Very generous!

-

Good plan! That sounds like exactly what I need.

-

If anyone has tips for how to non-destructively clean cast aluminum - specifically, the throttle body, and two parts of the huge intake manifold - I'm all ears. They're a little stained and dirty-looking. It's raw cast aluminum. I suppose silver paint could help but I'm not sure I want to go there. Apart from cleaning, the throttle body needs to be disassembled and cleaned out, just as a precaution. I have new bearings for the throttle plate axle, if needed. I probably want to plate some of the associated hardware as well. But I'm going on holiday for two weeks so not much is going to happen, I expect, but if it does, I'll post it here.

-

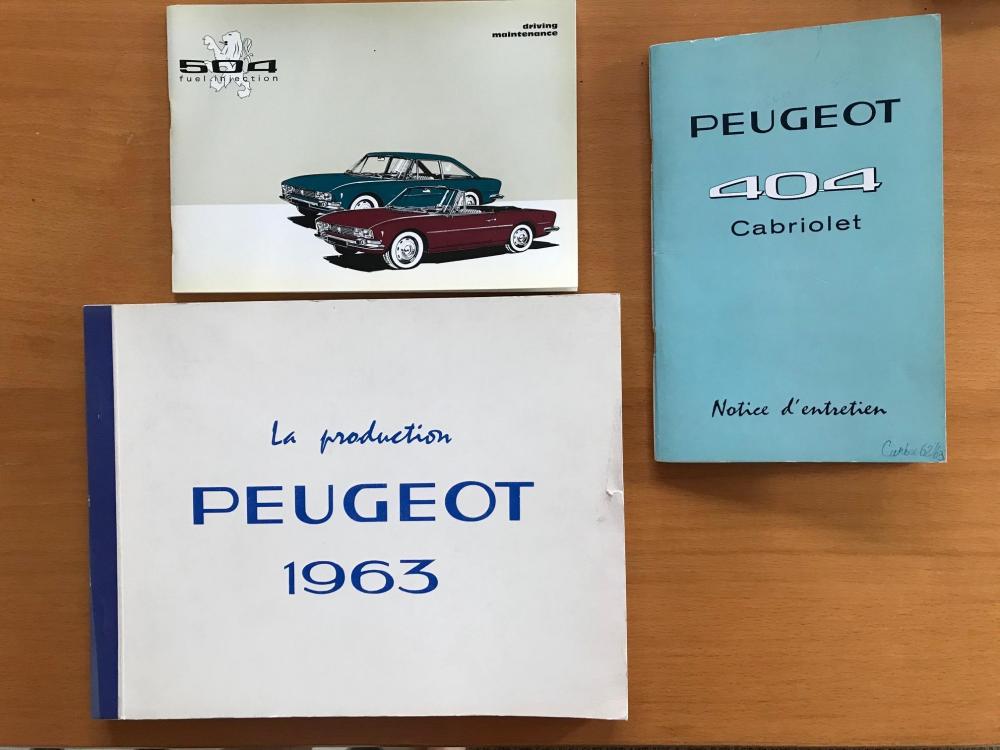

Unrelated to the restoration but I got these today. English language 504 C manual (my Dad wanted to buy one when we lived in the Netherlands in 1971 but he was told it would be illegal to import to Canada, which I think was wrong because he was in the armed forces and could have brought a non-conforming car back). French language 404 cabriolet manual, first edition I think. 1963 catalogue of all the various vehicles Peugeot made in that model year.

-

It was annoying, because at first they sent a set of three main bearing Lead-Indium bearings in 0.3 mm o/s which were OK but wrong.... I still have those too, second faulty set was no charge. But I figured any NOS they had there would be similarly damaged so I just went for some I knew were OK.

-

The correct set of NOS bearings sent by l'Aventure Peugeot were somewhat damaged (2 of them had bad chattering marks on them from being loose in the package) when they arrived so I bought a set on eBay out of Israel that had good photos of the bearing surface. 0.5 mm oversized.

-

Wow it looks lavender. Mine will be...black, after the block is hot tanked and thoroughly cleaned.

-

404 blocks were black

-

Victoria company. Yeah I think I'll do assembly myself unless the shop that does the machine work makes me an offer I can't refuse, and cheap. So I'm pretty sure I'll be doing it. Will post ample photos.

-

Thanks to Bruno Garovo for sending the right set of bearings which arrived today (anyone need a set of Lead-Indium 0.3 mm mains for a very early KF 3 main bearing engine?). I also got back from the powder coater the valve cover, timing cover, sump, coil holder and spare wheel. Photo taken just now in Victoria in the smart hatch, in the light rain.

-

Any Peugeot owners from Vancouver, BC?

Mike T replied to 85PugSTI's topic in General Peugeot discussion

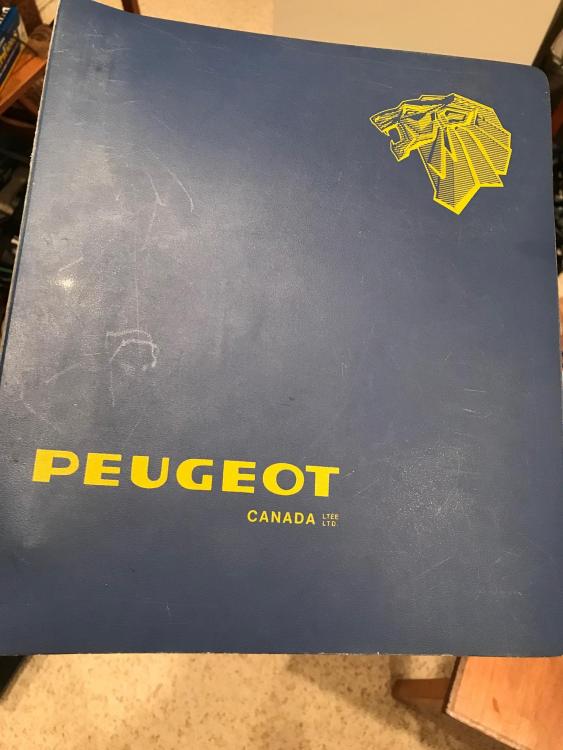

Well now, that's just not so! Peugeot Canada Ltée/Ltd. existed between 1958 and 1983 or thereabouts. 25 years more or less. Here's a plastic binder as a prop. The disastrous Chrysler Canada distribution deal - which ensured that the 505 tanked in our market (compared to the 504 that outsold it 2:1) only lasted through 1987. Four years. Don't you love zombie threads? -

I ordered some 0.5 mm oversized main bearings sent from Peugeot but they sent the wrong ones - three main bearing lead-Indium 404 Injection mains 0.3 mm oversized (visible in the photo). So the correct ones have been sent today, and it seems they don't want the incorrect ones back. Also in the shipment were the things in the photo. New stainless steel instrument panel trim for when I eventually build the Jaeger sports instrument panel, plus a spare oil pressure sending unit. In the bag are some original type small diameter hose clamps for the heater hoses. I also got some English language owners manuals of cars I've had (404C, but with carbureted engine) or wanted (504C). The latest bit (504 C owners manual, La Production Peugeot 1963 and a first edition 404 Cabriolet French language owners manual should be here soon. I will work on extracting the sludge trap plugs from the crankshaft this weekend. Likely have to drill all 4 out. A set of the missing brass banjo fittings for the front drums has been sent by a kind soul in France, a 404 Club member - free! I'll send him something as a thank you.

-

Good luck! This is bringing back bad memories of my 405 DL. I changed its starter twice. Then the Mercedes that replaced it ate two starters in short order. But since its warranty ended, the past 200,000 km or so, it's been fine.

-

I had to pay $82 to bail this new old stock camshaft out of the post office: Coated in the usual preservative, looking good.

-

Still oil-related, this arrived from Sochaux this morning. I have another shipment of stuff arriving probably next week.

-

Thanks. The slightly worrisome thing is that these things often fail and the 2 year warranty of the one I posted the specs of would go some way to alleviating that. That company also sells the Branson units.