-

Posts

82 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Collections

Everything posted by wadehilts

-

Hey @luizsantana! Thanks for sharing your knowledge! It looks like you had your block bored out, and liners installed! Nice. For reference the engine I'm using is an original XD3T from a 1985(?) 505, it had 45k original miles and I haven't done any internal mods to it. I'm hoping the pistons, cylinder walls and bearings will all be in decent shape. You brought something to my attention about the head gasket. @Bean you may find this interesting too. I went digging in the Peugeot spare parts manuals and found a lot of different part numbers for the head gaskets. See picture below. Translating from French, it appears all part numbers with "<b" after them include the head bolts and washers, while those without "<b" do not have bolts and washers. The "<b" part numbers all correspond to earlier head gaskets. It's my understanding that the XD3T bolts are not torque to yield, I don't know if anyone can confirm that. It also appears that two different versions of the head gasket existed - one with asbestos and one without. I don't know which is better, but it appears @luizsantanahas one without asbestos. Looking on serie04.com (see other picture) I was able to confirm that the asbestos head gaskets appear to have less material, so if I had to guess I should shoot for a non-asbestos part number. This leaves me with one last question. "crans" is notches, what does that mean? It appears there are 2, 3 and 4 notch versions of the head gaskets. Does this correspond to some piston size tolerance or something? It appears that the 2 notch gaskets on serie04 are 1.53mm and the 4 notch are 1.73 mm. It appears @luizsantana has the 1.53 (2-notch) version. I can purchase 0209.C7 and 0209.D1 on serie04 now (both 4-notch versions), I guess I would choose the later version 0209.C7? Since I don't know what head gasket in is the car now, I am thinking I should probably go ahead and replace it. If sourcing a 2 notch version would be better I can keep searching too! I guess it would give me a little more compression? My best guess is the thicker gasket is for a head that has been skimmed?

-

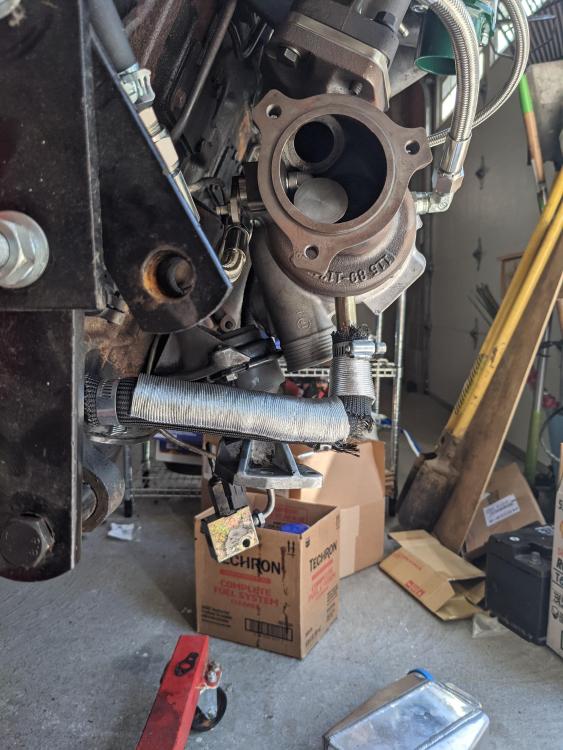

I ended up taking Rabin's advice, I cut the OEM hard line and spliced it into the fitting for the TD04 turbo hardline. The TD04 sits a significant amount lower than the OEM turbo does, but I was able to get away with a quick 45 degrees right off the bottom. then I have double heat shielded oil hose running to the barb on the block. I also got a turbo blanket for the exhaust housing, so that should keep my rubber components safe from getting cooked. Here are some pics of the final set-up! Next up I need to fabricate a mounting bracket for the wastegate actuator - which will be dependent on how I end up deciding to clock the turbo and route the intake plumbing.

-

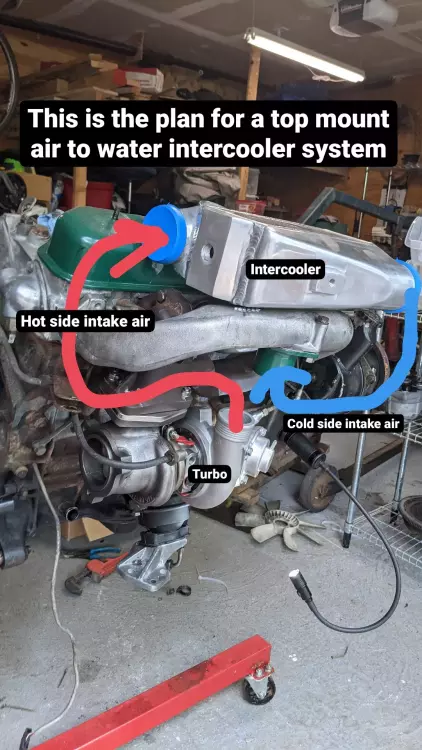

@Bean Been figuring out how the boost controller would work out and sketching out plumbing a little more today. I think I can say for almost certain, without even putting the engine in the car, that this IC would not fit in a vertical orientation. However, this doesn't stop me from drilling and tapping a hole on the top of the IC (see photo with X on IC), where I could install a bleed screw on the highest edge of the IC. that should allow me to get 99% of the air out of the intercooler when I bleed the system. I'll have the filler cap inline with the 3/4" hose somewhere where I can make sure its the highest point in the system - even if only during bleeding. Big thanks again to Rabin for doing years of research before I even knew anything about engines, my project would have been much less exciting if it weren't for your counsel! Wade

-

Yeah this isn't going to work, my oil return line can't go lower than the drain cock. But I got the coolant lines working! Back to drawing board. going to try to get a AN fitting adaptor and have it run out to as big of a barb as possible

-

Hey Arthur, what workshop manuals do you have? I might be interested! Also, an update. I've been having a bear getting the oil return line sorted. The hose barb on the XD3T block wants a 7/8" ID oil hose, which is hard to find. I finally sourced one and then used a 90 degree adaptor to go to 3/4" oil line which was close enough to clamp onto the 5/8" drain cock from the turbo. Although at this point I'm a bit worried I've ran out of vertical space to properly gravity drain the turbo. I've heard the turbo drains need a clear path to the block without pooling being possible. I think the low spot on my hose may be baaarely too low. I can cut the barb on the turbo down though and get another inch. I have a lot of heat sheild material on the hose too so I'm hoping it won't be cooked by the exhaust heat. I also plan to use header wrap where possible too to minimize heat radiation. Here are some pics:

-

Hey @Bean Yeah the EGT sensor isn't in a perfectly ideal location, but I'm hoping it will work well enough / there will be enough swirl in the manifold to maintain an accurate reading. Hugh provided me with the html files for the now defunct Australian site "Hot Five-Ohs". Here is their unverified opinion on BA10 torque limits: So that's a different perspective out there. 300 Nm corresponds to 220 ftlbs. I'd be interesting if some of the other members of this forum, particularly the tuners in Australia, have any comment on this. @Stewart?

-

Hey @Bean I'll look into the boost reference details. My turbo already has a fitting that I could easily run a line to, so I'm tempted to just use it. But if that's inferior I won't. Seeing mixed opinions online, I'll do more research. EGT probe is going to be installed in the EGR block-off plate shown in the picture. Good to know, I'll use a similarly floppy spring in my WG actuator kit. Also, @PeugeotPilotand I would like to know more about your research on BA10/5 torque upper limit! What has led you to believe that it can handle 300-350 ft lbs? Wade

-

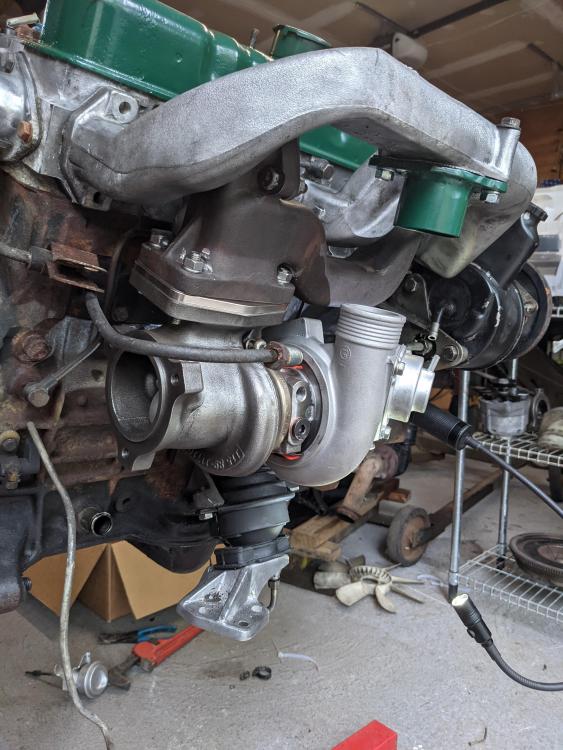

OK great I'll check in with Giles. He's had my pump since mid June so I'd expect that it will be done soon! Unfortunately my boost gauge is part of a dual-purpose EGT and boost gauge that I got. I will measure boost from the manifold for that gauge but the boost controller will be referencing right off the compressor housing. So I'll at least get to see the pressure drop across my tubing! The boost controller gauge I will probably hide away in a less conspicuous part of the car. I really won't need to see it once it's dialed in too. I've heard that about the weaker spring being better. Makes sense, it will probably allow the controller to more quickly actuate the wastegate with less resistance. So I will probably use a 8 psi spring or something like that for my WG actuator. I'm getting close to being ready to drop the engine back in so I can see exactly how tight it will be and where I should run intake plumbing stuff. Any recommendations on custom intake fabrication? I saw frozen boost had a bunch of silicon hoses that I could probably order once I know exactly how it will all fit. Wade

-

I wanted to share another couple neat things I've done so far. I used the opportunity of my EGR block off plate to tap two 1/4" NPT fittings. I got some ISS pro gauges that will display EGT, Exhaust Back pressure, and turbo boost. Since I'm doing EBC, I'll have a redundant boost gauge that is also the boost controller. But I may hide that anyways. My biggest technical concerns now are: How the hell do I time the pump? I will just have to go by ear? I'm using a XD2S pump with an XD3T engine. Worried about first start up going smoothly tbh Fitting the intercooler and plumbing in a spot that is easily bled / makes sense / works.

-

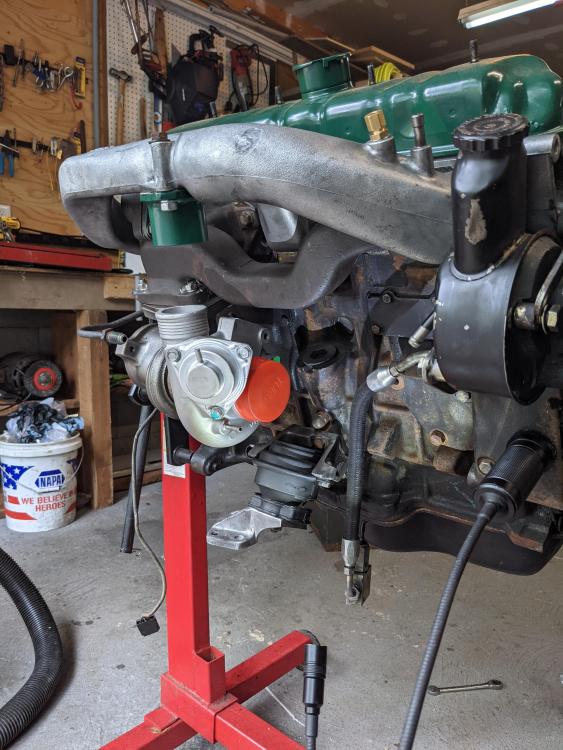

Hey @Beanthanks for your input! Some great advice. Some responses: Piston Diameter: I did a fair bit of research on this and the VE pump part numbers show that XD2S were all 10 mm and XD3T were all 9mm (for the VE pumps at least). This is explicit in the part number. E.g. VE4/10F2125R67-1 has the application code R67, and the -1 demonstrates automatic. Automatic Transmission models have a different cam speed, e.g. 2125, than the manuals - but pump head is the same. The manual and automatic XD2S have the same 10 in the part number for the piston head diameter. BA10/5: good news there! hopefully I'll stay just below anything catastrophic Intercooler mounting: you're right about the bleeding. My current setup is going to be tricky at best. My problem is that with A/C and the 604 engine bay I don't have very much room to work down there. I think for now I'm gonna just have to wait until I can drop the engine back into the car to see how everything fits. Worst case, I may have to route my IC coolant hosing and everything such that the IC can be repositioned to bleed it upon install without cracking open the system. Gonna be a headache for sure.. Turbo fasteners: good call there! like an idiot I had used stainless. A little metallurgy research showed me that was a bad idea. Best I could do at the hardware store was 10.9. It's a bit of a pain because the T3 flange takes M10 bolts and the volvo takes m8, and they each require studs at the same spot. I went with M8s and used the M10 holes as pass thru holes but that definitely came with its own set of challenges and it was tricky to get everything assembled. Now that I'm less nervous about the BA10, I'm down to do boost control. Why not! I'll look into the product you recommended. I have a manual boost actuator kit that has variable spring sizes for different boost levels and well as actuator arm length. It is pretty tight back there so the OEM actuator was an impossible fit, especially after re-clocking the turbo. Wade

-

Ah that's good to know. I sent Giles pictures and information about each pump. I think he does a lot of internal modifications, but I'm not sure exactly what they are. His recommendation was that I go with the XD2S pump but he was aware that the XD2S engine was smaller displacement and had less power output.

-

Hey all, Build update! Big thanks to @Beanfor giving me tons of advice and informing much of my decisions in this build! I've settled on my project plans, and hope I can get 160 hp / 290 ftlbs out of this XD3T. Here's what I've done/am doing: Having Giles rebuild VE pump from an XD2S (they have a 10 mm pump head, where XD3T pumps had a 9 mm) to support 20 psi of boost. Putting in a Volvo TD04HL-13T, with an 11 blade billet wheel. I was able to use a T3 to Volvo adaptor plate for the exhaust housing. I also had to use the straight flange from a different TD04 to get things to fit better. I used the frozen boost air to water intercooler and plan to mount it above in the intake manifold (see pictures). Here are some pics of my progress so far! Still waiting on the VE pump to be finished. Rabin, as you've seen on the facebook threads, there has been some concerns raised about the BA10/5 getting lunched by nearly 300 ftlbs of torque. Hugh Logie seemed to recall that the rated torque for the BA10/5 was only 220 ftlbs. Although I do know that the 4.0L Jeep straight sixes put out 224 ftlbs in 1988 and they were in front of a BA10/5. I am probably going to be the guinea pig on this at the end of the day. I was considering doing EBC too but currently don't have that set up.

-

OK I kept doing my research on upgrading the turbo and learned a bit on how to read turbo flow charts. For the 2498 cc XD3T, I assume a max rpm of 4150 (shop manual's max power rpm) and a VE of about 2.1 to correspond to 16 psi. That lands me at an absolute max of 384 CFM of airflow (which by the 2.5 rule, corresponds to 154 HP - sounds about right). It will most likely be a good amount less than this due to inefficiencies in the intake/exhaust but I'll call it a good upper limit. Looking at compressor charts for the vd04hl-13G and 13T, it looks like both turbos would probably work. The 13G taps out at around 365 CFM and the 13T more comfortably hits 400. I think I'll probably just go with the 13T so I have a little wiggle room and am not getting close to any limits that may result in smoke. It should still spool nice and fast too which is something I definitely want, while also leaving room for hitting that 150 hp / 280 ft lb target handily.

-

XD3T AFM & Electronics - plea for information

wadehilts replied to Joe Ernest's topic in Diesel specific tech

My friend has an 85 XD3T 505 sedan and he simply disconnects that AFM. All of the electrical crap hooked up to the engine was purely for emissions and can be removed without any issues. -

They offer this OE Bosch air to water intercooler pump https://www.frozenboost.com/liquid-air-adapter/water-to-air-pump-0392022002-p-1001.html?osCsid=tlge2fucudjhiid1m706m21b37 Apparently it only draws 2-3 Amps, which isn't bad. From what I've read they usually just run continuously when the engine is on (simplest way for me would be to wire it into the shutoff solenoid circuit, but I maybe could wire in a tach relay and use the tachometer output on the xd3t ve pump to turn it only only when engine is spinning?). I suppose setting up a thermostat would also be an option too, but if it only draws 3 A I'm not too worried about it. It's +$70 to upgrade to this pump, so it'd bring the total to around $350. I think I'm gonna go this direction, I'll keep every apprised!

-

Well currently, the frozen boost site has a discount on a kit that would include the intercooler, pump and heat exchanger - all for only $280! https://www.frozenboost.com/liquid-air-intercooler/water-to-air-intercooler-p-1034.html You're not wrong about the KISS principle tho...

-

OK! After some more measuring I think I found the solution that FrozenBoost would formally approve of: I can mount the heat exchanger they offer specifically for the water to air intercooler that is a 30-row, 10x13x2 radiator right in front of the radiator on the drivers side. If I remove the old 12" A/C fan and replace it with a 10", that would give me plenty of room. Then its just a matter of shoe-horning the intercooler in anywhere, which I have plenty of space to make that happen and routing the intake hoses. I think we've got a winner.

-

Update on my scheming: https://www.frozenboost.com/air_water-ic/small-liquid_air-intercooler-p-210.html I found this water to air intercooler. It's 11x9x3.5" in size, which is quite compact - I bet I could squeeze that in if I take out the air filter!. It says it's rated up to 450 CFM / 350 HP. I ran the XD3T stats thru a CFM calculator that gave me about 420 CFM max for the 2498 cc with a volumetric efficiency of 2.0. Another rule of thumb is to multiply the HP by 2.5. If I do that I get 375 CFM. So it looks like this intercooler would be big enough for the XD3T with 15 psi of boost and making 150 HP. Happy to hear if anyone else has opinions or thoughts on that. As far as heat exchangers go, their standard option for the intercooler I'm looking at is a 19 row 10.75x11x2" radiator. I'm wondering if I could maybe get away with their next size smaller which is a 13 row 7.5x11.5x2 or even the next size down 10 row 5.75x11.5x2 - which would fit very nicely under the bumper at that size!

-

XD3 to XD2S Parts Interchangeability?

wadehilts replied to SouvenirCup's topic in Diesel specific tech

Wow. Well if you do go back I'd definitely compensate you for those intercooler parts!! You mentioned we've talked on fb, DM me there (I don't know your name so I'm not sure which person you are) -

XD3 to XD2S Parts Interchangeability?

wadehilts replied to SouvenirCup's topic in Diesel specific tech

Hey SouvenirCup... you found an XD3TE in the US?? those are incredibly rare. Did you get the intercooler parts off of it?? -

Thank you! I'll keep that in mind. I know the N9T** 505s had a special grill and the 505 hood is a obviously gonna be a bit different, so there's a few unknowns there, but the top mount intercooler would be a nice "true to Peugeot" way to go. Where are you located? I'm in Portland, OR.

-

XD3T Injection Pump reseal/ rebuild. XD3T workshop manu

wadehilts replied to Joe Ernest's topic in Diesel specific tech

Hey Joe, if you could share that compiled translated XD3T manual I'd much appreciate!! Wade- 7 replies

-

- xd3t

- injection pump

-

(and 2 more)

Tagged with:

-

Also, I found this quick guide to VE pump tuning. I'm not sure how far you can take an XD3T VE pump boost-wise before needed a different spring, anyone know? https://www.tstproducts.com/vepumpadjustment.aspx

-

Yeah that's a good idea. If I get rid of that big foam cylinder air filter that will buy me some real estate. Still going to be tight as hell in there tho! I'm hesitant to do any major surgery on the 604 too as I'd like to keep the body as original as possible.. Do you have an idea of how you'd duct in the cold air? Another idea I had yesterday was setting up a air to water intercooler. If the sizing works out, it would allow me to run water lines in a similar fashion as the oil cooler lines. Then I could mount a heat exchanger on the other side of the body below the radiator, right next to the oil cooler! Assuming all that fits, I could swap in a cone-type air filter that takes up less space, and then hopefully be able to put an air-to-water IC anywhere I can fit it.. Thoughts? I'm going to consult some local fabricators on this, as I don't know how big the IC and heat exchangers will need to be to support 15 psi of boost. Wade

-

Yeah my biggest challenge is going to be getting the intercooler AND the AC equipment stuffed into the engine bay. Exploring my options and taking measurements now.