keebs

Members-

Posts

209 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Collections

Everything posted by keebs

-

The fuel table is completely independent of the ignition table. Ignition is pressure vs rpm, I started with stock idle advance and simulated a distributor curve up to 3500 then just guessed. I can upload graphs if you'd like, just let me know what you want to see. I don't find carbs any less precise or complex than efi, I tuned my 550+hp 358ci v8 to idle at 14-1 cruise at 16-1 and get over 20mpg.

-

I don't see why not, all wiring/components are the same except for the ignition ecu.

-

Well first it asks for injector size and number of cylinders, then you do a required fuel calculation so the VE table numbers are close to your actual volumetric efficiency. I used the auto tune, but accel/decel events muddied up the results too much for anything other than a starting point. It's easier to set up a log with all the important points rpm, map, tps, curr. VE, corr. VE, target afr, actual afr, accel pw, egt, spark, coolant temp, air temp. It'smore time consuming, but you get better end results.

-

The program might err on the small side to keep people sane. Size of the turbo is all about application. Do you want to drag race, road race, offroad, street? Go small for oem, tad bigger for performance, tad bigger for road course, then full retard for drag.

-

.7 bar at 24lb.min might be making more heat than power. I would opt for a slightly bigger compressor.

-

It was just an objective thought, hope it didn't come across wrong. I don't think any ecu's on the market have a that function, but you could give LINK a call and ask for it in the next update. That turbo looks just big enough to do what you need. She'll spin up pretty quick with a boost controller.

-

I've spent much time thinking about your bov setup. I like the idea, but think it needs to be taken a step further to be better than a mechanical unit. Maybe you could use dtps/dt so that the valve was triggered by a throttle decay rate rather than vac or single tps percentage.

-

Sounds pretty straight forward, I might have to make one. Save your pennies on oil, heavy diesel oil has the same ingredients as most high end racing oils.

-

I use the copper pipe method with construction style earmuffs. A diy electronic set would be nice, but you might end up having to discern between electrical noise/static and det. I've also got a det sensor wired to VEMS, I just haven't gotten around to making it active. I had a brief conversation last year with a VEMS distributor, and I believe he said it wouldn't do knock correction while either sd card logging or just logging in general. Setting up knock detection in VEMS isn't the easiest of tasks anyway, I might not even set it up.

-

Is there a 505 cross reference list anywhere?

keebs replied to bergxu's topic in Technical Discussion

Google universal sway bar end links, or you could use some sealed heim joints from the hardware store. -

Sounds pretty beefy down low. Now you've got me thinking about what 505 motor I should build. What kind of internals are you using for it to accept boost?

-

I think you may have lost it. All kidding aside, I do pretty much the same thing without the math. I always think of fuel injection as a carbs more sophisticated less hands on brother when making adjustments. When it comes to ignition, I used the curve for a small block chevy since it's head is similar enough for a start point. Under boost I took out 1 degree per psi which worked out pretty nice. If you have a good friend let them drive while you wear the det cans and make changes, or every time you go for a ride wear them and make the changes when you get home based on logs.

-

Sweet, I hear you on the fuel map I spent a few hundred miles getting mine smooth. No need to get the numbers off the injectors, I have the same ones. These injectors were designed for ULEV vehicles, they can handle 6 bar without trouble. Bump it up to 3 bar or more, it might run better with less fuel.

-

I looked through the software again, and it's interesting to say the least. Under closed loop control does it only allow stoich? I saw you can configure its shutoff points based on map/rpm, but I'm mildly confused about how it works. Is the lambda target table only used for auto tune? I might have to buy one of these ecu's just to tinker, maybe put it on my tractor or something.

-

I ran the innovate WB feeding the stock ecu before going stand alone. Closed loop afr is best left alone. A better solution would be a map or tps based switch to kill the o2 ecu input and force open loop which is easily tuned with fuel pressure. Now wideband sensors do have a long lifetime (50-100,000 miles), and have been used by German OEM for many years. For some reason the innovate controller burns them up. The new lsu4.9 sensor has more data points and doesn't use free air calibration. It's not very well supported yet, but is soon to be the new standard.

-

The pics wont enlarge for me but if I understand right tps/rpm is your lambda target table and map/rpm is the fuel. If that's the case +1 for link. The maps make more sense now, didn't realize they were showing inj pw. What kind of injectors are you using?

-

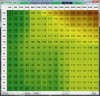

Excellent, glad we didn't get lost in translation. If you're using full sequential injection idle and cruise can be pretty lean. 14-15 at idle with a rich "hill" below for idle stability and up to 17 for low load cruise. Are you talking about a blended table where it switches from map/rpm to tps/rpm at 30%? If yes, it's a good strategy. But just for fun let's say were going down the highway 30% tps -40kpa 2500rpm (I know bear with me) the grade gets steep and we're feeling lazy so we hold throttle steady. As we climb map rises into boost (-40 to 70kpa) and rpm stays constant. So since rpm and tps stayed constant (stayed in one load cell) the ecu had to compensate fuel by WBO2 for a 1.1 bar pressure change. Just a little food for thought.

-

I downloaded the LINK software a few minutes ago. It's laid out a little more difficult than VEMS, but has all the same thingamajigs and doodads. I wish i could be of more help, these things aren't easy to discuss through print. If you download VEMStune I'll send a config file so you at least have something to compare against.

-

Map vs rpm is said to be a better calculation. Does LINK require a 0rpm bin. If not I would rescale for 700-idle-1300-... no sense having all those "unused" cells. Let me see if I can download the tuning software to get a better grasp on how it works

-

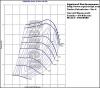

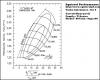

Here's a pic I pulled off google. You can see the cells below 1500rpm are all similar. The example I gave was to depict an over fueling condition at start up. If you send me a config file I would be more than happy to help.

-

Stewart, it shouldn't take too much fuel when cranking start at 0 and work up a few percent at a time. Your VE table is only multiplied by cell. So if hot idle is 60ve at whatever map/rpm at 2ms pw, and during cranking its 80ve with 3x multiplier thats a lot of fuel. Rabin, I hope that pic is clear enough. I drilled there for ease of service, and to keep the leads from melting.

-

That was probably it. Might want a flex fuel sensor too just for kicks.

-

Rabin, I would suggest a GM open element iat and GM closed element clt sensor, or any pair of sensors that use the same resistance curve for consistent readings. VEMS doesn't yet support the new lsu4.9 WB, but you can source one from a vw jetta or something for 50 dollars. A second map sensor for active baro correction would be nice. One thing you might want to start thinking about is a firewall grommet, or a fully sealed bulkhead connector of sorts. For the cold weather you can pretty much guess the coolant curve, then adjust as it warms up. You can set cranking enrichment based on the warmup table. There's also a compensation table for iat/tps which comes with some base numbers that are probably correct. There's also a clt/map ignition table, and iat/map ignition table. I'm still waiting for winter here, but don't see it being and harder than tuning for summer.

-

Cant see the page. VEMS is pretty simple, but some things could be made better. My biggest gripe is the tuning software doesn't quite fit my laptops screen right, so its pretty good overall.

-

Yep, VEMS, MS3, Haltech, and many others have some kind of auto tuning feature. While it's a very helpful tool in the beginning, it is by no means perfect. I used it for a base then smoothed out the 3d map and used data logging for the rest.