-

Posts

1,297 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Collections

Everything posted by Mike T

-

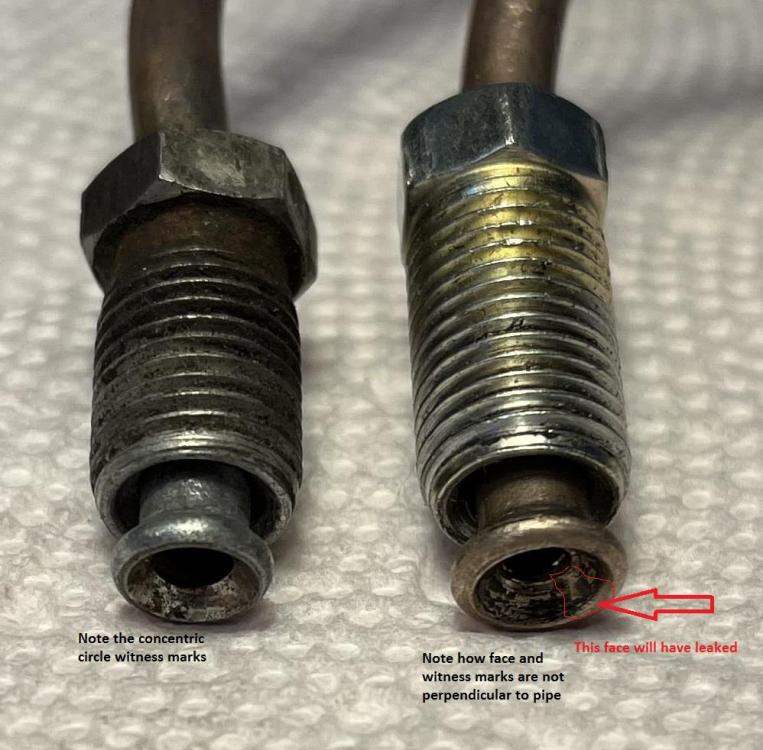

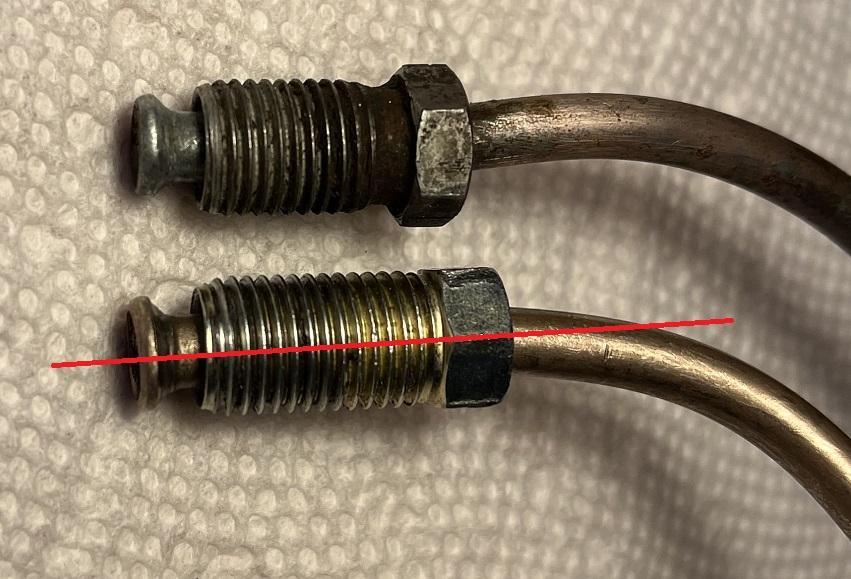

...and it turns out that the unions likely were the problem with my new brake lines.The reason is that the Hydrovac 404s have short external brake lines connecting the two cylinders - these have bubble flares, which I dutifully made, but the fittings that I used the first time were the same over all lines, which in hindsight is not correct, because the bubble flares use about 1/3 the conical taper of the regular flares. So those lines would have been where the air was being sucked in.My friend Tim Bowles in Victoria gave me a set of used fittings and this is when I finally clued into the problem. So I've removed and cleaned up 4 originals and will make sure to use them on the new lines I make up. Feeling optimistic about this now... Left is the inter-cylinder fittings for the bubble flares and right is the other type of fitting.

-

-

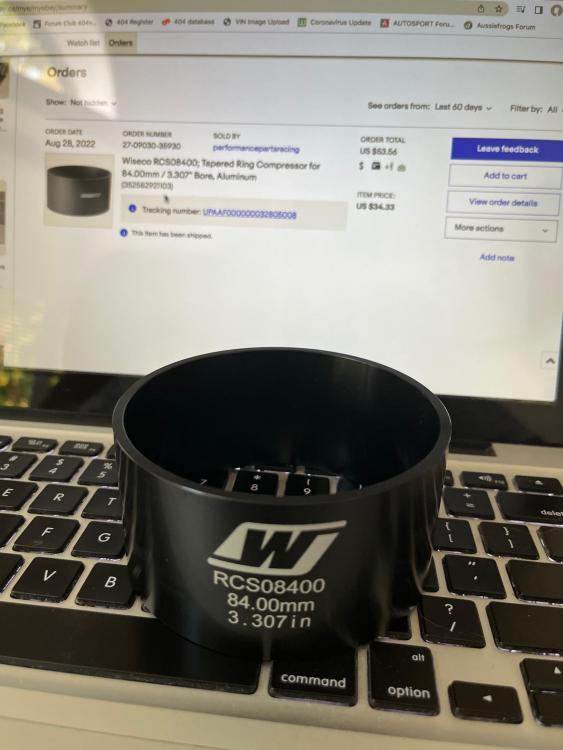

Nothing has happened since the summer began other than me getting some more parts for the brakes and a taper type ring compressor, which should arrive Wednesday. The 10 mm UNF fittings I got from France had about 1/3 of the width of 45 degree taper on them compared to the originals. This meant that a test flare I made was mangled by the cylinder and the sealing would be crap. So.....I have resorted to re-using original fittings from 404s - plating them - because they're the only ones that I can say will work for sure. I have resisted cutting up the original brake lines because in the worst case scenario I could re-use them, knowing they seal well. Coming soon: engine reassembly and brake line manufacturing phase 2.

-

2513 now....14.6% of the total ever made are now accounted for. The rate of new discoveries is slow but progress is still happening.

-

I seriously doubt that the 1989 505T weighs only 2730 lbs. It's more likely over 3000.

-

Blast from the past: John Coltman's 404 Injection

Mike T replied to Mike T's topic in General Peugeot discussion

No but you can email him at [email protected] ....of course it's without the hyphens in between the words.... Do you have a Peugeot, or did you formerly? -

I'd recommend taking the wiper axles apart and re-lubing them. They look as though they're dry. Might be a hell of a job with the dash in place though.

-

A 504 XM or XN - 505 XN6 unit should work on a 404 block.

-

Well this won't help you, but Peter Gallagher at Automotion in North Vancouver can do centreless three stud wheels.

-

Back to the future, like the timed port injection of a Kugelfischer engine ;). Unnecessary, but elegant.

-

Bomjour!! Introduction, my first Peugeot, 1981 505 TD

Mike T replied to LBC28730's topic in General Peugeot discussion

Welcome! About 125,000 were exported to the USA, or roughly 10% of all 505 production. About 4,500 were sold in Canada. The sales here were extremely poor due to Chrysler selling them 1983-1987 and the abandonment of the traditional Peugeot dealers by Peugeot Canada around the time of its introduction..... -

No. It's an $8000 CAD car in that condition.

-

Total of 404C cars registered is 2503 now. New discoveries are becoming less frequent as the total goes up. I still think there are 3000+ survivors. Like Pokémon, I've got to catch them all.

-

That style of brake compensator was introduced in the 404 in September 1966 for 1967 models. Glad the car's running well.

-

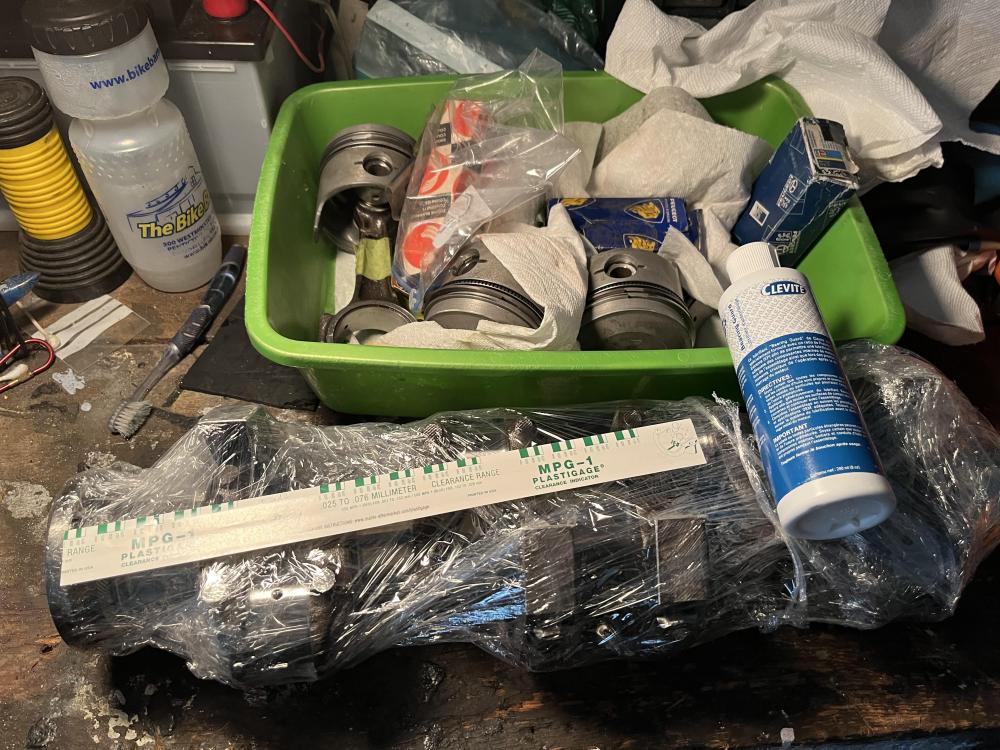

Today I cleaned the super sticky black residue that the shop in Victoria had smeared all over the liners and liners seals at the lower and upper ends. This required acetone and a lot of toothbrush work plus a scriber to get the thicker bits off. Once it was about 99% clean, I test fitted the liners without the seals to verify protrusion. All were more than 0 mm and less than 0.06 mm so it's good. Also cleaned gasket residue off the oil pan mating surface and the timing cover mating surface. Now I'll have to clean out the block because it's been open for a few months, though covered, and then start reassembly. I'll try inserting the pistons from the underside of the liners, which have a chamfer, once they too have been cleaned off (this is how it's done for some Renaults).

-

Dean Hunter sent me two replacement shells for the two 0.3 rod bearings that were damaged in transit earlier this year, so now I have two complete sets. Hope to begin some work this coming weekend.

-

Also got more brake parts, the latest of which arrived today. It's the brake proportioning valve, also NOS like the other one that I bought 15 years ago, but initial indications are that this one will be usable. At the very least, I can try all my new brake lines in these fittings to make sure the ends fit properly.

-

Yesterday I got the crankshaft back. The act of polishing it at the present 0.3 mm undersize was sufficient to eliminate the high burrs that scored the new bearings the other shop had put in. There are very small tiny divots in the journal surface left, but these will not be of significance going forward. About the way the damage occurred, it's obvious that the other shop had inserted the pistons into the liners from above, whacking them in with a mallet and smacking the journal with the rod bolts. Rookie mistake, only they're not rookies. Factoid: 404 liners (probably many other Peugeots, and Renaults too) have a chamfer at the bases clearly intended to facilitate piston insertion from below. That's the correct way to do it.... Had it been done this way in the first place, the crank would have been fine. I also neglected to get the first shop to install the new pilot bushing. So I had Chuck at Mid-Island Machine and Engine do that job. None of his standard pullers would get the old one out, but he thought the grease hydraulic-ing trick would get it out, but it didn't...so he threaded the bronze bush and then screwed a shaft in to pull it out. On the 404 at least, there is a grease seal at the end - Chuck said that American cars don't have that but it's a good idea.... Anyway..... I was given a container of Clevite bearing shell grease to protect the crank bearings for initial assembly and startup. I was also advised to prime the oiling system with the engine in situ so the first start is not a brutal one. I'll rig up a manual pressure system through the oil pressure sending unit to do that. Given the previous shop's inattention to detail, I'll also take the rocker system apart again to verify that the oil holes on the shafts are in the correct spots and put some assembly grease in there too. I may being engine assembly soon but the braking system needs to be in working order before the engine goes back in. Crank wrapped after washing: Inside the shop:

-

Well here is the update. The owner of the parts who was vacating the (now sold) house (Walter) made a deal with the new owner to rent the place for $2000 a month so he can try to sell his parts stock, which is all stored there. Pavel, the guy who was in touch with Walter, tells me that he thinks the parts will ultimately be sold in a lot to someone but at least be saved. Pavel also told me that he thinks Walter will lose money by staying there as it's unlikely he'll derive $2000/month from part sales. In any case, the parts should still survive and not be pitched into the garbage, which is the main thing. We've no idea who will end up with them, though.

-

Welcome! I have a register for all known Canadian Peugeots so if you could let me know the serial number and "504 number" (e.g. 504A93) I'd sure appreciate it! There are 3750 cars on the list so far.

-

I also over-squeezed the flaring tool when finishing the ends...plus the bleed screws are super clean so likely air was being sucked in there too. The new unions will come in soon and I can start over, much more carefully, this time. I've also ordered a new distributor junction (the bronze thing on the X-member) in case my over tightening has messed it up. The iron cylinder female union threads in the cylinders and brake hose unions should be fine. Interesting idea about reversing the flow. Will consider that.

-

Some members on Aussiefrogs supplied the following doctored photos to help the diagnosis. Also, it was correctly noted that the bleed screws themselves are super clean and those threads will be leaking with a vacuum bleeder. So I have some robust ideas to follow up on the next go-round.

-

I have a few tips now: firstly, I have ordered the proper 10 mm with 24U from Serie04 fittings for the lines and I also think that I had the end of the tubes too far out of the block when making the flares, and that messed up the sealing. So now we're going to make a new set up and hope for a better result....

-

I think I'll get some new fittings from Europe and start over. I don't know anyone with a Motive but it would be nice.

andRegularFlare(R).thumb.jpeg.57d714552be4a1ab9fe30d7bb3ec1071.jpeg)