Alfanatiker

Members-

Posts

120 -

Joined

-

Last visited

About Alfanatiker

- Birthday 10/09/1984

Profile Information

-

Gender

Male

-

Location

Norway

Recent Profile Visitors

3,090 profile views

Alfanatiker's Achievements

-

I've been in contact with one Frédéric Massy at this company, and they actually make coilovers as well as cheaper but sporty stuff for the 505. But it is rather expensive. In 2018 their cheapest system was 1470 Euros and the most expensive was 3530 euros. Still only coilovers in the front I believe. https://soben.fr/

-

Is it possible to find some big end sizes and specs for clearance during engine rebuilding? I am talking about the numbers with normally 3 digits behind the whole mm number. So proper technical information. I've tried to look in the manual from the Finish page, but couldn't find specs for rebuilding.

-

Do you still have some of these bearings? Is it for rods or main bearings? I need both. But would like to know what you have first before I decide how I need to grind the crank.

-

It all depends on the small and big end sizes. I would like to keep my forged H-profile rods if possible. In worst case I would have some special order parts by size. It all comes down to cost really. It's also possible to get a bespoke crank for about 2500-3500USD. But I really don't have that kind of money to use on a crank. In any case, I will not put in rods with a lesser quality than what I have. So OEM Saab or Cosworth is out of the question. But Chinese made forged could be. Unless it's cheaper to get usable oversized bearings. It's kind of silly to buy new rods, grind the crank even more AND modify rods, when all I theoretically need is either a supplier of oversized bearings or a used OEM crank that could be saved with a polish.

-

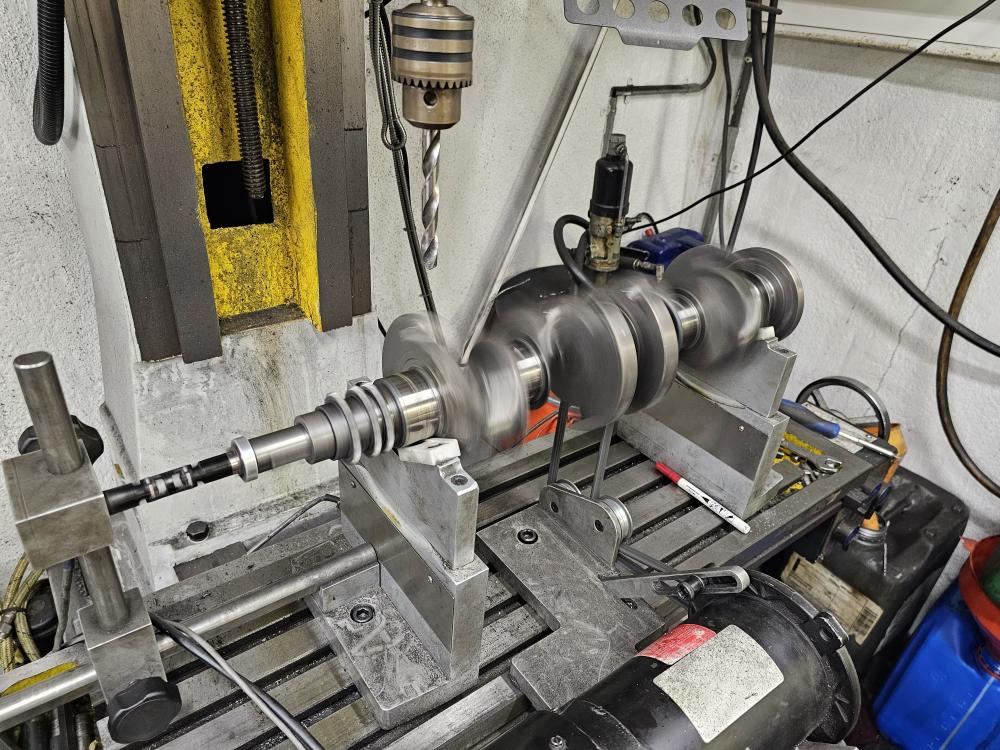

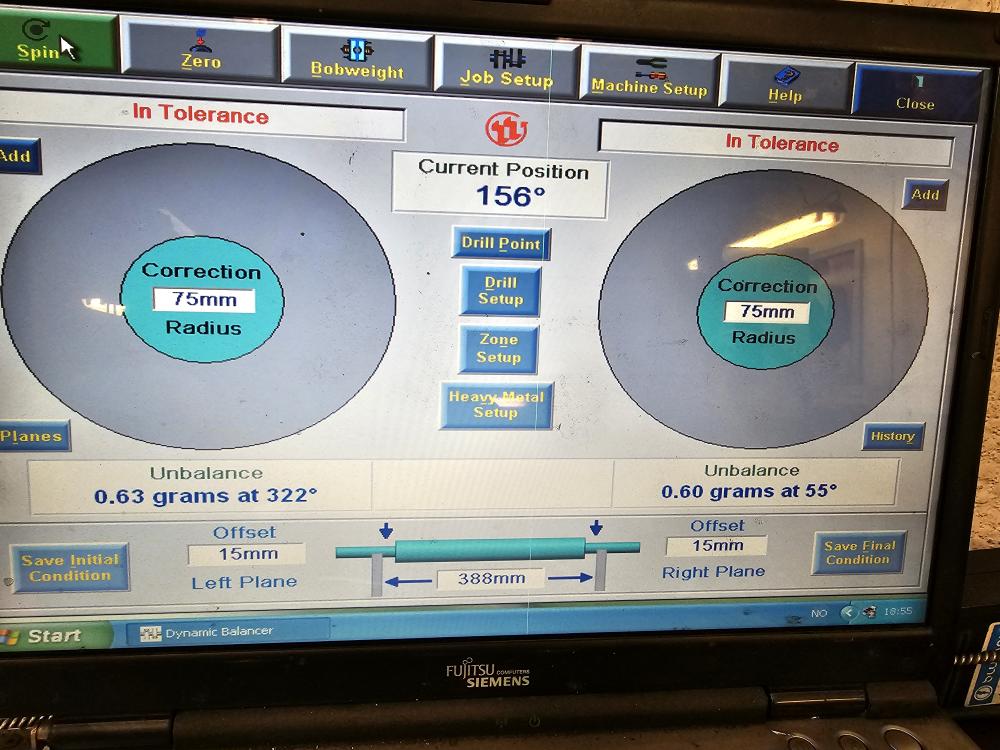

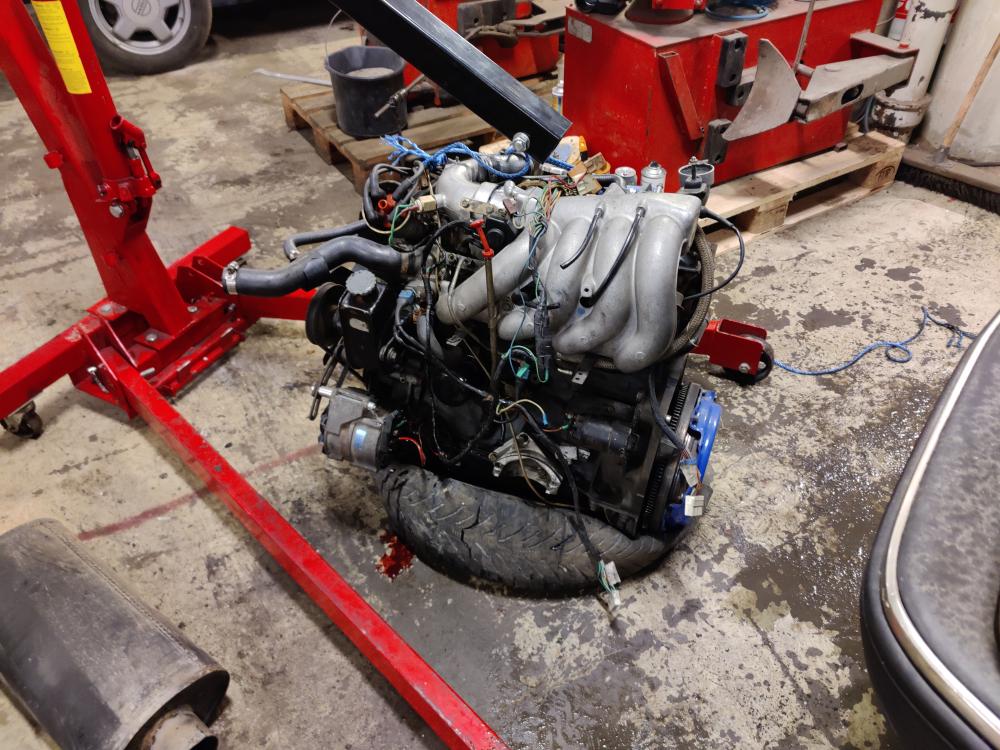

Just a little update here. After the last posts, I actually never used the car after the trip to the first owner. As I could hear a slight engine knock when the engine got hot. I didn't want to take any chances as parts are really hard to come by for these engines. So in October last year I removed the engine from the car, and dismantled it the day after. What I then found out was that because of a large dent in the oil sump, my pickup for the oil pump was smacked down in the bottom of the pan. And probably for this exact reason, the car couldn't produce the correct oil pressure. This is taking some time as money is somewhat limited nowadays, as well as parts are really hard to come by for these cars. But this weekend, my block is in a acid bath for stripping. And I will start with some machining when I can. But if someone know of a undamaged crank I can use, it would be really helpful. Both rods and block is 100% But crank is really bad, and one of the crank to rod connections is already grinded to the overdim bearing I was able to get. Even standard bearings is really hard to get hold of. Overdim is almost impossible. And especially when already ground to one overdim.

-

505 turbo (or other N9T original) crankshaft wanted

Alfanatiker replied to Alfanatiker's topic in For Sale / Want ads

As they are quite heavy, I would think that yes. The engine was rebuild in a really "amateur" way when the car was painted. And the problem that made the engine fail the last time, was not fixed. When I disassembled the engine now, I found out that the oil sump is so badly dented, that it hits the oil pickup. So I recon it is way to close to have decent oil flow. This time I will do it properly myself. I'll try to take pictures and do some updates in my project thread along the way. -

A mistake was made by the Lithuanians that grinded my crank for overdim bearings, and now I need to redo the work myself. And unfortunately I really would like to get hold of undamaged crank for my engine when I am completely overhauling it. I put the block in the acid for stripping today, and will take it out on Monday to assess the damage more. But I do think the block is 100% fine.

-

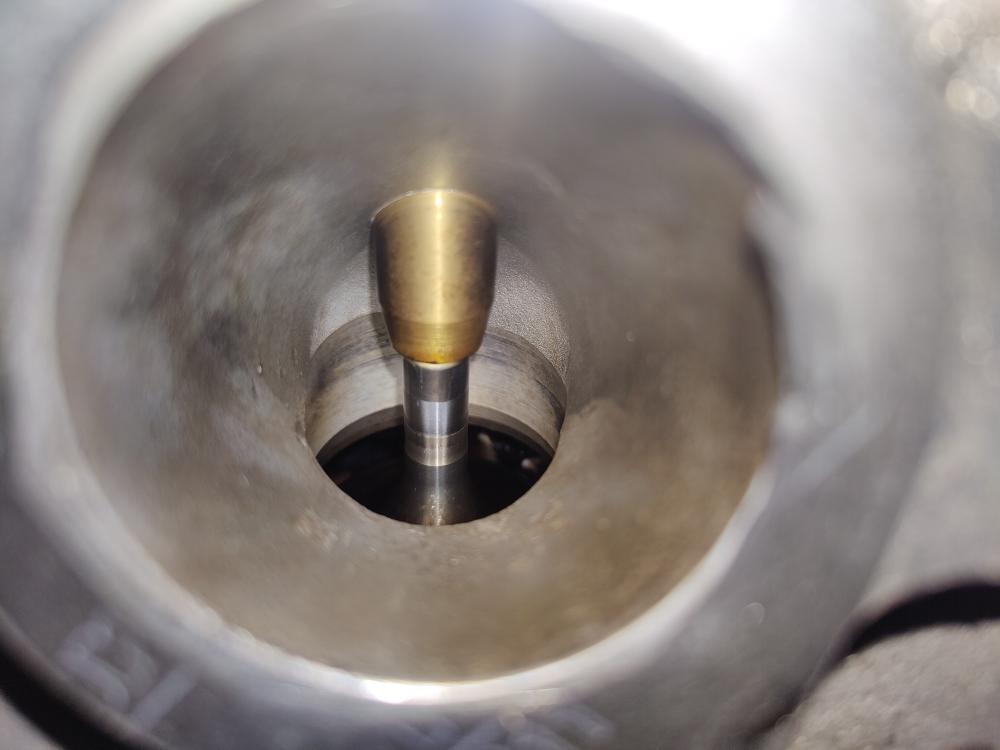

Is my 505 turbo head CNC machined?

Alfanatiker replied to Alfanatiker's topic in Performance and Tuning

It is for sure a sharp edge there I will fix when I first have the engine out of the car. But do you have any comment about the intake manifold? Why is it only 36mm when the head is 41mm? Why did Peugeot make it like this? Its like the head was made for much more power than the manifold. And since the manifold has such a large radius on the pipe, it is pretty much impossible to increase the runner size all the way to match the head. We have a very long bottle neck on our engines. -

Is my 505 turbo head CNC machined?

Alfanatiker replied to Alfanatiker's topic in Performance and Tuning

I didn't necessarily think it was a Danielson head. I was mostly very surprised about the fact that the intake obviously is machined especially from the side of the seat, and the fact that the intake manifold has as much as 5mm smaller radius than the head. The manifold is pretty stupid compared to the head port and makes for an incredible bottleneck in this case. Plugs are normal 14mm btw. Regarding the abrupt edge, I recon you are talking about the "radius" before the bowl, and not something that should be similar to the edge in the exhaust ports that has the lose short pipes to seal between the head and the manifold? The port is at least smooth all the way in, and is either machined or probably has the nicest casting surface I've seen in a head before. -

My intake in the head are approx 41mm (so rather large) and appears to be machined from both sides. And the intake manifold is only 36mm so it is not even a close match. Could I be a owner of some head that is worked on?

-

How much do you want for fabrication of one with a T3 or maybe even T4?