-

Posts

25 -

Joined

-

Last visited

ganun's Achievements

Newbie (1/14)

0

Reputation

-

Looks like its easy enough to remove the 5 nuts and take a look for the big time cracks! Maybe they are due to abuse.

-

Just got a great looking rebuilt center section from Durabuilt Turbo in Chicago, $250. Looks like a lot of extra work to clock it correctly so the oil inlet and outlet AND intercooler and manifold connections properly line up! Think this is the procedure I'll use: 1) Leave the cold and hot housings loose so they can spin 2) Bolt turbo to manifold 3) assemble finger tight EVERYTHING , ex mani to head, intercooler, oil lines in and out, wastegate actuator 4) snug a few of the accesible housing bolts 5) remove all again from engine to tighten and lock the housing bolts 6) final reinstall Whew!!

-

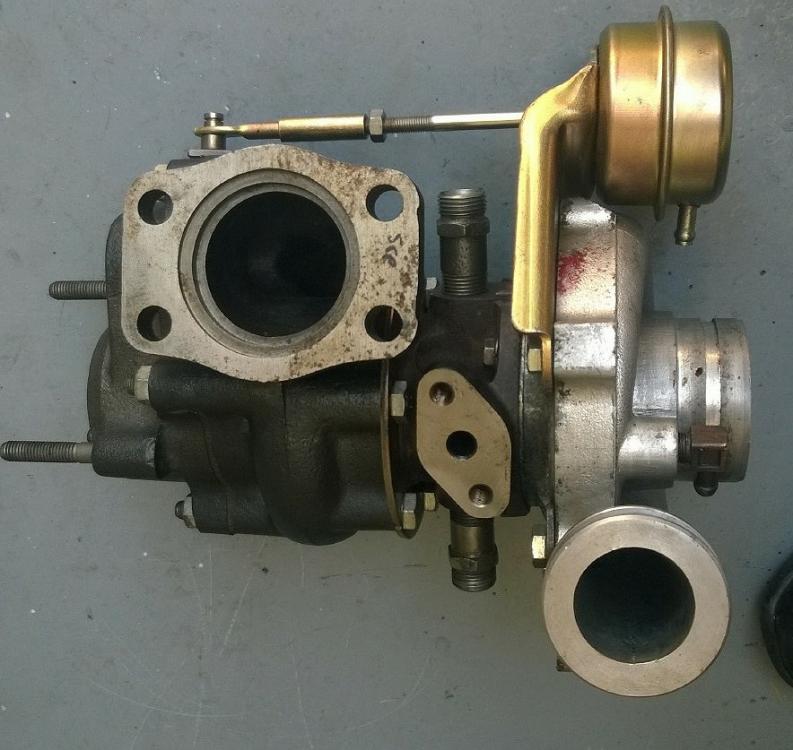

Wonder the difference on presssure tap location, some have it at the outlet , your picture shows it at the start of the scroll? 1st pic is early .48, tap at start. 2nd pic 89 .48 tap at outlet.

-

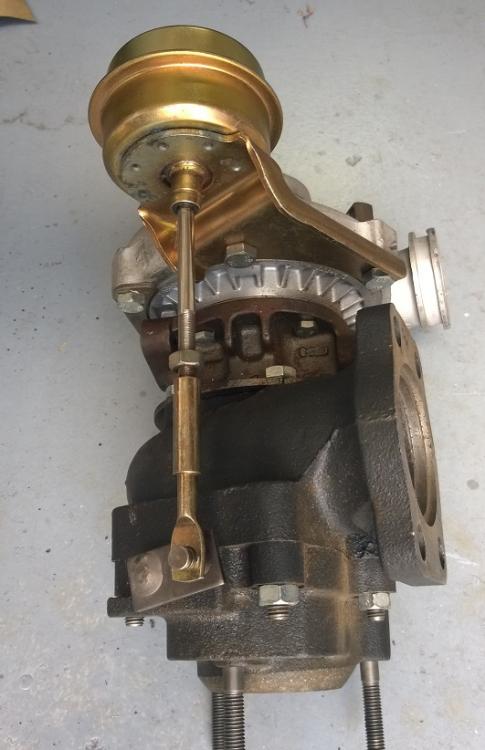

Thanks guys, its settled then. The issue has been put to rest. I have a sort of hybrid then, using the N9T 2 piece 48 turbine housing , with a watercooled center and common compressor side. The reason for this is simply that it allows the use of a new Danielson 16lb adjustable wastegate actuator thats been sitting on a shelf for years. I am satisfied that the center section and rotating wheels are the same and so is the compressor side.

-

BH says the opposite, i.e. later versions are 2 piece ?????????????? I am getting another from Dubarr, 89 car with blown hg, lets see! Eventually one will get a rebuild. This (is/was ) my best attempt, but now I'll have to see if a 48 one piece shows up.

-

Just great, are you sure that only the 85 had the 2 piece hot side, the Dani kit only fits the 2 piece. Also I have yet to see a 48 one piece. Out of a sample size of 4.

-

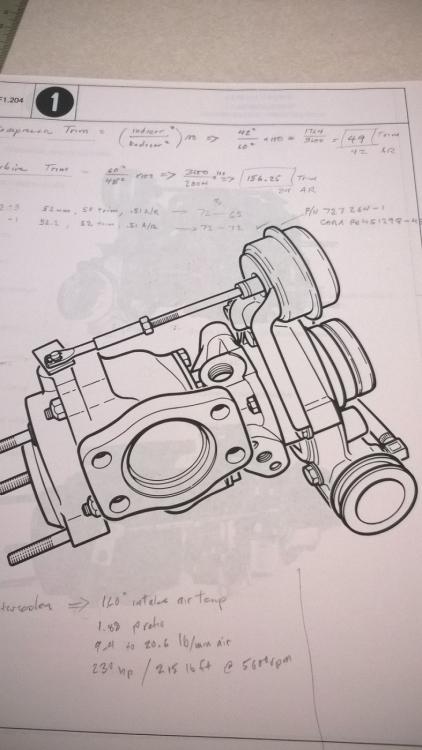

Summary of findings. N9T- 42 AR intake, 36 AR exhaust, single piece exhaust casting, angled wategate acuator, 48 AR exhaust, 2 piece exhaust casting, straight actuator link, no water-cooling. N9TE- 42 AR intake, 48 AR exhaust, 2 piece exhaust housing, straight wastegate actuator, 36 AR exhaust, single piece exhaust casting, angled actuator link, watercooled. N9TEA-42 AR intake, 48 AR exhaust, single piece exhaust housing, angled waste-gate actuator, watercooled. The compressor and turbine wheels are the same for all versions, same trim, compressor trim is 49 (42/60), turbine trim is 156.25 (60/48). So the difference is in the turbine housing: 1) 48 AR two piece housing N9T 2) 36 AR single piece housing N9TE 3) 48 AR single piece housing N9TEA A visibly larger hole for the exhaust to spin the turbine on the 48 AR version. This change should be noticeable at higher rpm, no loss of boost.

-

While cleaning the carbon from the inlet to the turbine on the old N9TE look what's cast into the inside. AR# Haven't looked at the 48 housing yet.

-

Thanks Rabin, Yeah I am excited about this now,I asked BH to send a water cooled center section then I'll get it overhauled ( no sense installing questionable parts). I'll ask around to find the correct way to adjust the actuator link length Good web site...

-

Mystery SOLVED! My 89 never had the correct turbo since I bought it in 95. The turbine housing has been the one piece, AR # unreadable,....... should have 2 piece housing AR #48. The GOOD,.... an actuator I got 15 years ago as part of the Danielson sport kit ( head, cam, h gasket, actuator) didn't fit the turbo in the car and I always wondered why not. Well it fits perfectly with the 2 part exhaust housing. The new mystery is what was my old turbo, maybe it was the type for the 87s N9TE ?????. Pics below show the differences in the hot side housing and how the new actuator fits the two part housing.

-

Yeah, ecu control.... Here are some pic of a spare turbo I got from BH , looks like the correct type: 1) Comp outlet #42 2) Ex side, correct # AR 48 3) p/n 466-718, TBO 346 4) Except.....during a rebuild someone put the wrong center-section, NOT water cooled! The pic from the shop manual looks like style in the pics below, note the nuts on the exhaust exit section.

-

11.6 psi , while stock, the book shows wag and sedan same p/n. IRC one of the ecus is different.for the wag. Btw , I run the sedan ecu. can't measure A/R but I measured the green label which has a compressor trim of 49, turbine trim 156. The turbine casting seems to have a A/R 36 cast into it.

-

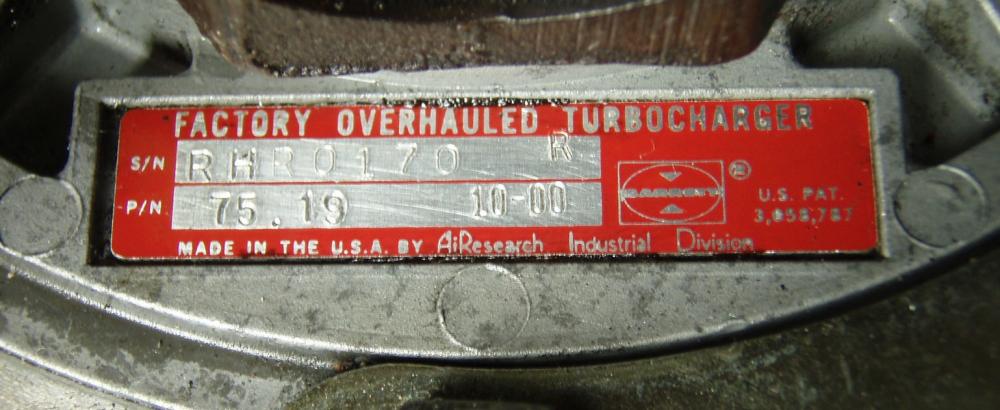

Thanks Rabin, Its good to know that a T3 kit works, a shop should be able to rebuild it, but I'm sending it out, I'm not familiar with the details, the Limit Engineering and Majestic Turbos shops looks good to me, any experience with these??? The low/no boost condition pretty sure has been ID as a draggy turbo, i.e. it spins freely but stops rather quickly, (almost immediately) after the twirl test. The RED label turbo in the car now, has lasted 2 years in service, shows Peugeot part no. 0075.19 which is for SEDAN up to 87 and WAGON up to 88. So i've had the wrong unit in my car these last couple of years, should have had 0075.23 ( SEDAN from 88, WAGON from 89) for my 89 wagon!!!!!!! Green label in the pic is from the previous turbo, before the RED label, one that was in the car lasted 20 yrs and 275k miles before it started to smoke, but it must have been replaced by the PO, the label shows no ref to Peugeot #s. I wonder what the differences are between the two, 0075.19 and 0075.23 ......anyone???????

-

Part number from 89, wagon...model TBO 346 Garrett part number 466 718-2x

-

Name: Peugeot 505 Turbo Category: North America Date Added: 2016-03-30 Submitter: ganun Peugeot 505 Turbo